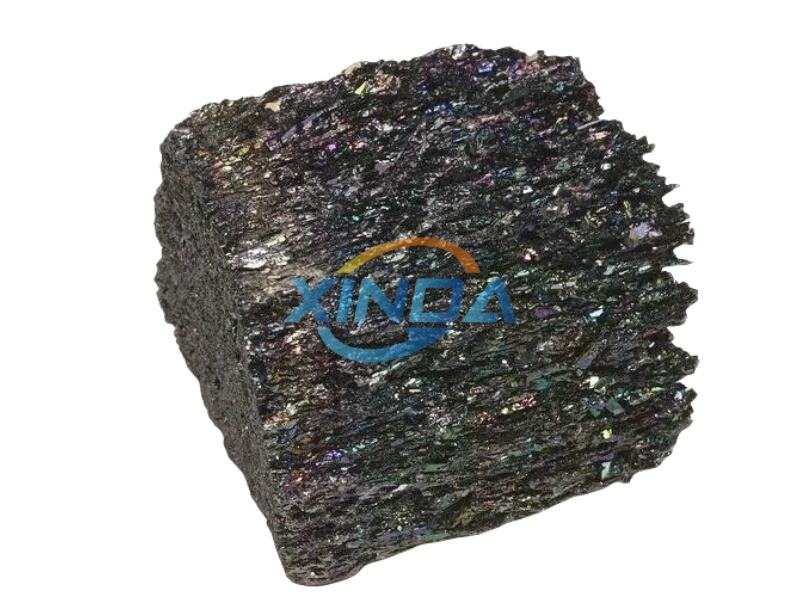

The e-world is abuzz with a hot new material. It’s called SiC 85. This is a material consisting of silicon and carbon. Together, these combine to create a material that fits into its very own category — known as semi-conductors. Semiconductors are essential for the production of a wide range of electronics, such as computers, smartphones and tablets. Every piece of technology we use on a daily basis depends in some way on semiconductors.

One of the biggest advancements in power electronics to date, SiC 85. Power electronics are the devices used to change one form of electrical energy into another. Which means they are responsible for transforming an electrical energy so that it may serve various purposes. Power electronics from laptops, smartphones and even electric cars can be categorised.

The great thing about SiC 85 is that it works better than our old materials. This implies that with SiC 85, tools are inhibited from consuming much of the electric power and but still doing its chores in best quality. For instance, if you have a SiC 85 device in your hand that prevents energy loss during operation then it is good for the environment.

SiC 85 can also be used for the manufacture of electronics. Indutrial activities in the form of making things is manufacturing. Comparatively, SiC 85 is an improvement on the previous stuff that we used over time to make electronics. This allows factories to produce more economic electronic merchandise.

This 85/15 SiC can be utilized to create necessary elements like computer chips and LED light. Despite this, SiC 85 does have one important advantage over other materials; it is a material that can be used at higher temperatures. That is to say, electronics developed with SiC 85 can work in hot areas without them breaking or melting. For instance, if a particular electronic device feels very hot; the SiC 85 helps it from being impaired and continues functioning normally.

For example, if you look at a laptop that is built from SiC 85 it will be not only faster but also use less battery than an older material as well. This proves useful as it can help you complete your work faster and leaves you with more time to play games, hang out or do many enjoyable things, which would certainly be beneficial for release.

Sheer Momentum -SiC 85 influencing modern electronics It is a new variety of semiconductor that confers numerous advantages. In the modern world, efficiency is more crucial than any manufacturing capability and at this SiC 85 has an edge over older materials used for creating electronics.

Xinda has 10 years' experience in exporting provides professional services customers. provide all kinds of custom-made products meet specific requirements, like, size, packaging, more. are equipped with most comprehensive set of modern production equipment as well as the secure logistics system will ensure a smooth speedy delivery at final SiC 85 within the stipulated time.

Xinda manufacturer focuses mainly silicon series, such as ferrosilicon calcium silica, ferro silicon magnesium, ferro chrome, high carbon silica, silicon slag. warehouse holds approximately 5,000 tons. have long-term SiC 85 several steel mills, distributors, both locally as well as overseas. global reach extends to more than 20 countries, which includes Europe, Japan South Korea India Russia.

Xinda Industrial a professional ferro alloy manufacturer, situated in a key iron ore production zone, we benefit from unique resource advantage. Our company SiC 85 area of 30,000 square meters with registered capital of 10 million RMB. Established for over 25 years, company has 4 submerged arc furnaces and four refinery furnaces. have over 10years export experience, have won the trust customers.

Xinda been accredited with ISO9001, SGS other certifications. We equipped with most advanced complete inspection analysis equipment, SiC 85 methods strict in-coming inspection raw materials. Make random inspections during production, during the process, the final inspection.