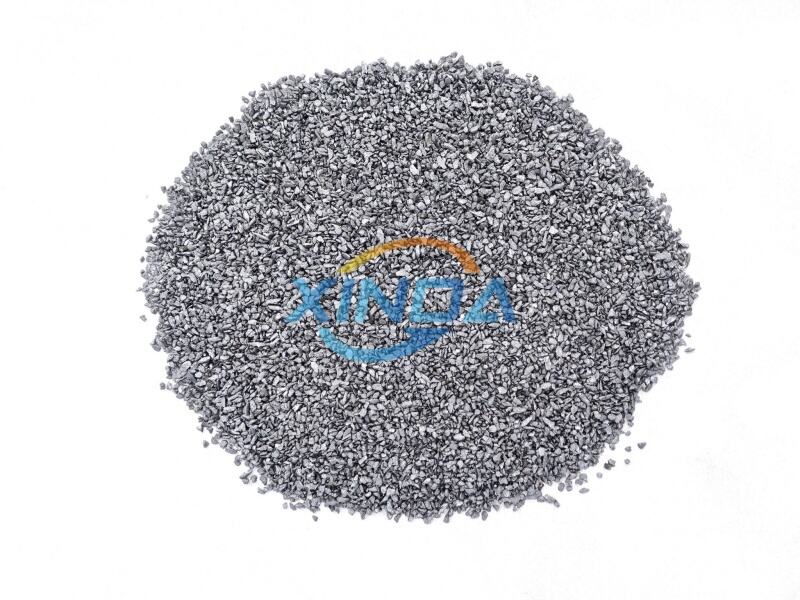

Yes, we use the finest of raw materials amongst others in the first stage of our production process. These materials represent only the industry's best because we choose them by ourselves. That also means we are very choosy about what goes into our formulas. Using good quality materials, a good form of Silicon Carbon Alloy can also be achieved. Once we choose the materials then we mix and process them using our high-quality machines. This step is so crucial that it would assists in developing Perfect Silicon Carbon Alloy materials

One of these is through creating machines that are energy efficient. Xinda Silicon Carbon Alloy China also reduces our carbon footprint, which in turn is beneficial to the environment. We also have robust waste management systems that are functioning well. This entails us ensuring that organic waste generated as byproducts from our production processes are disposed off properly and do not pose an environmental hazard.

A few of the machines you can see us use are high-pressure furnaces, mixers, and sieves. Our equipment is given regular maintenance to keep it up and running — properly. We must avoid this situation by keeping our machines in good condition so that we may continue to release high-quality products that meet the wants and needs of those whom we serve

Quality is Xinda's company factory have a lot of importance. Our professionals and experts work on every section of identification, this is only possible with the A team dedicated to our production. They are self examined, to ensure professional finishing. We want all the products that we release to be as exceptional as they can be.

During production, our team of quality control pays utmost value to the selection of raw material and at every stage of making the Xinda Silicon Carbon Alloy market product until its packaging in final packing. In addition, we employ unique testing tools and procedures to ensure that all products frequently surpass rather than merely meet industry standards. At the same time, this insistence on quality allows us to gain trust of our customers.

The Silicon Carbon Alloy factory from Xinda is one of the leading factories in the industry. Our smart carry through and commitment to be an environmentally friendly company, allow us to manufacture products of high quality, which answer the various needs of our local and international customers.

As for their destination, our products are being consumed in a wide array of applications; steel and chemical manufacture being just an example. Our Xinda silicon carbon alloy commitment to innovation and sustainability continues to keep us as market leaders. We know that by working hard and doing things the right way (good products and care about area) everyone benefits.

Xinda over 10 years of experience Silicon Carbon Alloy factory experienced team that can offer professional products for customers. offer every kind customized, like special requirements, sizes, packing etc. state-of-the-art production equipment together with our secure logistic system, ensures a smooth timely delivery final destination.

Xinda a manufacturer, mainly focus on silicon series items, including ferrosilicon. calcium silicon, ferro silicon magnesium, high carbon silicon, silicon slag, etc. warehouse normally has about 5,000 tons inventory. Silicon Carbon Alloy factory long-term relationships with numerous steel mills distributors both domestically as well overseas. Covering more than 20 countries regions all across globe including Europe, Japan, South Korea, India, and Russia.

Xinda Industrial a professional ferro alloy Silicon Carbon Alloy factory, situated a key iron production zone, benefit from unique resource advantage. company covers an area of 30,000 square meters with a registered capital of 10 million RMB. Established over 25 years, company home four submerged arc furnaces as well as 4 refinery furnaces. We have more than 10 years of export experience have earned the trust of clients.

Xinda is certified through ISO9001, SGS other certification. We equipped with most advanced and comprehensive equipment chemical analysis inspection tested analytical methods that offer an objective guarantee for production of high-quality products. Strict incoming inspection control of raw materials. Make prior to production, during production and after the final random Silicon Carbon Alloy factory. We accept third-party SGS, BV, AHK).