Are you over looking at machines or tools that has rough bumpy surfaces? It can even make your equipment look aged and more prone to perform to its best ability. Fortunately, if you are going through this exact mess in terms of surfaces that need to be removed from the surface of a metal piece or logged on and covered with dirt, polishing carbide is an easy way for all your ownership needs. And the appearance benefit!

Carbide polishing is a process used to polish surfaces so that they appear extremely smooth. This takes advantage of a proprietary tool comprised tungsten carbide. It is available in several forms, as it can come in various sizes to adjust with different surfaces regardless of their size. During use, the tool rotates at very high speed and is pressed against rough surfaces. The coated scraping edge is drawn across, delicately righting the bumps and blemishes so they end up with a gold reflective surface. The process will not only restore the appearance but can also be beneficial in making the equ8ipment run better.

Fast and Clean: Carbide Polishing is an Excellent Option for Many Machines & Tools The main advantage is that the carbide tool which intended to a very long time. This means that you will be able to use it on some of the toughest surfaces without wearing out soon. This long-lasting construction will end up saving you money, because they require fewer replacements so soon and result in less need to repair offsets.

Carbide polishing is actually quite easy, but there are a few pointers that you must know before jumping into the rest of it. Examples include flat lapping, cylindrical grinding, and centerless grinding or through feed. With its different finishes and specific applications each method plays a unique part to make sure that you can realise the one for particular job.

Flat Lapping — The carbide tool is held onto a spinning plate and the rough surface of stone faces it. It is excellent shave for flat surfaces that allows you to make mainly large, smooth and shiny plates or blades. This is particularly effective in industries where precision and flatness are of a high priority.

Cylindrical Grinding: In the event that you have round pieces such as tubes and rods, then this process is used. When this is done, the carbide tool spins around fast enough to eliminate defects from the exterior while not altering its dimensions. This is important to keeping your shape strong while achieving a good finish.

Most metal working companies often require high quality finishes only those carbide polishing can provide. Think of the car manufacturers who need their auto parts to be a nice shiny finish so they give off that professional look. Carbide Polishing: This effect is achieved by means of carbide polishing. Many carbide polishing applications are used by a range of other industries -- from aerospace and medical equipment to the watchmaking sector which demands particularly high levels of polished surface finish.

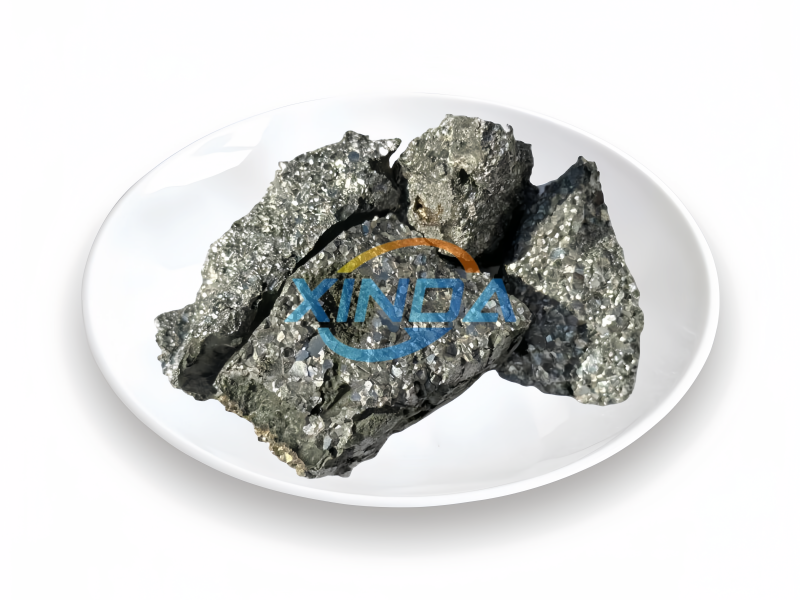

Xinda a manufacturer, mainly focus on silicon series products, such ferrosilicon calcium silicon, ferro silicon magnesium, high carbon silicon, silicon slag, etc. warehouse normally has about five carbide polishing tons stock. have long-term relationships with numerous steel mills distributors the United States as overseas. Covering more than 20 countries areas all around world, which includes Europe, Japan, South Korea, India, Russia.

Xinda accredited by ISO9001, SGS other certification. We have modern and thorough chemical inspection and analysis equipment tested analytical methods offer an objective guarantee the production of high-quality products. Strict carbide polishing inspection and control raw materials. Make pre-production, during production and after the final random inspection. We offer third-party SGS, BV, AHK).

Xinda Industrial professional ferro alloy manufacturer, situated key iron ore production zone, benefit from unique resource advantage. Our company occupies total area 30,000 square meters with registered capital of 10 million RMB. Established over 25 years ago and has four carbide polishing-arc furnaces, and four refinement furnaces. earned trust of our clients during ten years of exporting.

Xinda has more than ten years' experience exporting. team experts who can provide professional services customers. We offer every kind custom-made, such special requirements, sizes, packing and so on. are equipped with a range modern production equipment, well as the security-secured logistics system that assures a speedy efficient carbide polishing to the destination within the stipulated time.