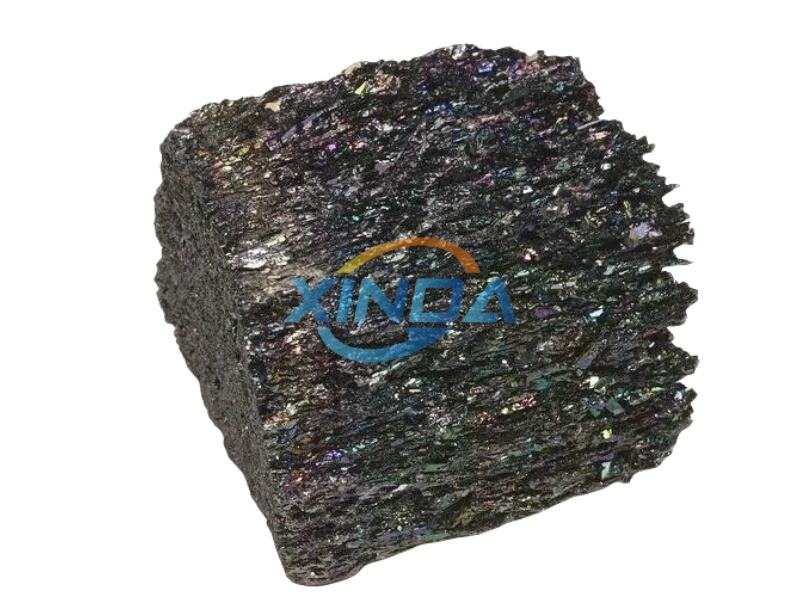

Carbon Silicon Carbide is the hardest and strongest. Actually, it is one of the most durable materials available. It is able to survive extreme temperature and harsh environment a lot better than current batteries. Thus, it is an excellent option for the jobs requiring both tough materials which can bear heat as well as resist harmful chemicals too. Due to its properties, industries use Carbon Silicon Carbide for creating high-quality products.

It also has high thermal and electrical conductivity. So it is applicable to electronic parts, including power semis. Semiconductors that are used to manage electrical power in equipment. Carbon Silicon Carbide is also capable of withstanding large amounts of radiation. Obviously, when you are going to any place in space for the material it needs to deal with an extremely degraded circumstance.

Carbon Silicon Carbide is used in a number of industries as well. One of an industry is the automotive sector that includes Car and Other Vehicles. Carbon Silicon Carbide is used in this industry to manufacture parts such as brake disc, fuel injectors or even sensors that check how car runs. It is the same metal that airplane and space craft factories use to build their parts, whichneed both strength for mechanical reasons but also durability when it comes to safety.

Carbon Silicon Carbide is also an important substance in the electronics industry. It is typically used in making high-performance electronics such as MOSFETs and diodes. They are so very important to controlling electrical signals in gadgets and computers. It also can be found in LED lights that are energy-efficient sources of light and it is the essential ingredient for cooling systems to prevent computer chips from overheating.

Carbon Silicon Carbide has already been studied for many years by scientists. They are always seeking to improve upon the glory that it stands at currently. In recent times, they have developed a new process to manufacture Carbon Silicon Carbide big and complex shapes. On the manufacturing side, that could enable manufacturers to make parts so much stronger and intricately engineered.

Additionally, researchers are working to improve how Carbon Silicon Carbide as a whole performs under extreme conditions. They have, as an example, discovered novel routes of manipulating the organisation of material on a microscopic scale. This makes it possible to increase its strength and durability, further extending the usability in even more harsher environments.

Novel applications for Carbon Silicon Carbide are as well factored. One example being how it is researched to be used in battery technology. Because of the potential to still build some truly exceptional batteries for things like electric vehicles, where more capacity and high performance over a wide range of temperatures is needed — since silicon doesn't tend to do well above about 300 degrees Celsius while lithium would happily go another hundred or so higher.

Xinda is certified through ISO9001, SGS other certification. We equipped with most advanced and comprehensive equipment chemical analysis inspection tested analytical methods that offer an objective guarantee for production of high-quality products. Strict incoming inspection control of raw materials. Make prior to production, during production and after the final random carbon silicon carbide. We accept third-party SGS, BV, AHK).

Xinda is an established manufacturer. concentrate silicon series items, including ferrosilicon. Calcium silicon, ferro silicon magnesium, high carbon silicon, silicon slagged. warehouse typically stocks around five carbon silicon carbide tons stock. have long-term agreements numerous steel mills and distributors both locally as well as overseas. Covering more 20 countries regions across the globe which includes Europe, Japan, South Korea, India, Russia.

Xinda has more than ten years' experience exporting. team experts who can provide professional services customers. We offer every kind custom-made, such special requirements, sizes, packing and so on. are equipped with a range modern production equipment, well as the security-secured logistics system that assures a speedy efficient carbon silicon carbide to the destination within the stipulated time.

Xinda Industrial a professional ferro alloy manufacturer, situated a key iron ore production carbon silicon carbide, benefit from unique resource advantage. Our company occupies total surface 30,000 square meters with registered capital 10 million RMB. Established more than 25 years and has four submerged-arc furnaces and four sets refinement furnaces. We have gained the trust our clients during past ten years of exporting.