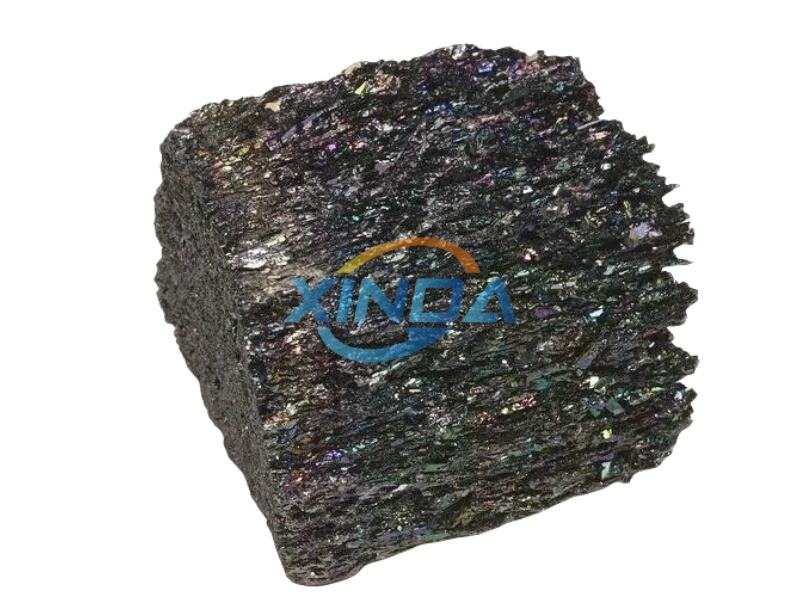

Ferro silico is specialized material that goes into steel. It is alloyed with other metals for strength. Xinda Ferrosilicon is high in silicon and iron, features that make steel able to withstand high temperatures and heavy weights.

An important advantage of ferro silico is it helps in increasing steel quality. Steel becomes rust and damage resistant, hence, when ferro silico is introduced by steelmakers. This results in longer life for ferro silico-made products and lesser maintenance work.

Ferro silico is used to produce special properties in the metallurgical industry. It also has a high melting point, so it can withstand the intense temperatures of steelmaking. Xinda Ferro Silicon Magnesium is furthermore strong and mouldable, so can be used in many ways.

Ferro silico is useful in the manufacture of iron and steel because the resulting product is stronger and has a longer life. In the absence of ferro silico steel would be softer and would break more readily. Xinda ferrosilicon alloy also assists steel items to hold out to daily use much better.

Good quality control is required when ferro silicon is used in plants. This ensures proper finesse of ferro silico. Hopefully quality control will prevent issues that can arise when Xinda ferrosilicon ferroalloy is used. By examining the production and testing the final product a company can have confidence the steel is of good quality.

Xinda Industrial a professional ferro alloy manufacturer, situated in a key iron ore production zone, we benefit from unique resource advantage. company covers space of 30,000 sq meters with registered capital of 10 million RMB. Established for over 25 years, company has 4 submerged arc furnaces and four refineries Ferro silico. have over 10years export experience, we have won the trust of clients.

Xinda is manufacturer, mainly focus silicon series products, such ferrosilicon calcium silicon, ferrosilicon magnesium, ferro chrome, high carbon silicon, silicon slag, etc. warehouse usually around five thousand tons stock. have long-term Ferro silico with variety steel mills and distributors, both domestically internationally. global reach includes more than 20 countries including Europe, Japan South Korea India and Russia.

Xinda has more 10 years expertise in exporting offer Ferro silico service clients. offer a wide range custom products which include special needs, size, packaging, etc. advanced production equipment, together with secure logistic system, assures an efficient prompt delivery the destination of your choice.

Xinda certified by ISO9001, SGS other Ferro silico. have advanced and complete chemical inspection analysis equipment tested analytical methods that offer an independent guarantee the production top-quality products. Strict Inspection and control raw materials. Make prior to production, during production as well as final random inspection. We support third-party SGS, BV, AHK).