Part of the way that we do this is through a process called ferro silicon production which means to create an alloy known as Doing so. Which you'll be able to use in collaboration with churning out steel Made up of about 2 parts, and arguably the most essential alloy on earth in todays modern age: SiliconIron(()=> FerroSilicon The combination of these two parts creates an alloy that is not only stronger than steel, but also resistant to rust and other forms damage. There are a multitude of materials that we use to make ferro silicon, and machines/services like high pressure decarburization techniques which guarantee the utmost quality product for all your needs in the steel industry.

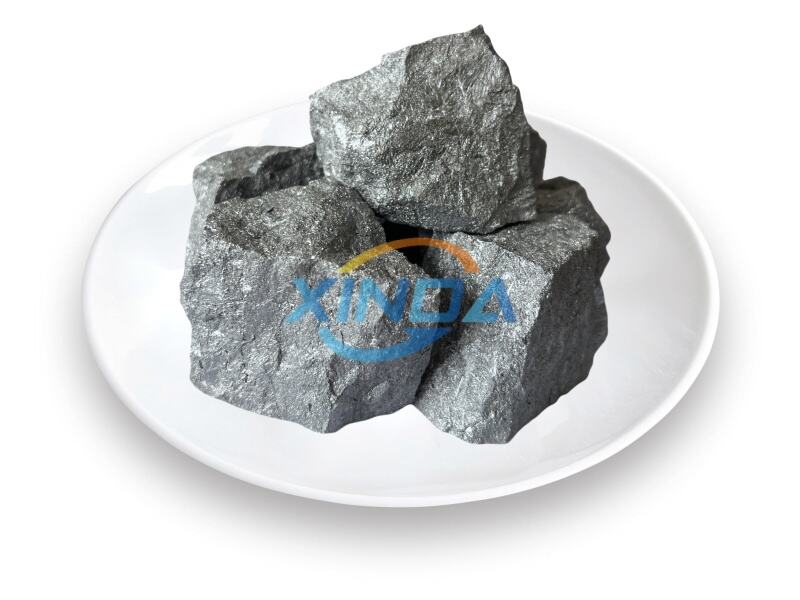

Ferro silicon needs some main raw materials to successfully produce it. At the heart of this are silica, coke and iron. Silica is a compound produced from a natural element such as sand, gravel or even rock and serves an important function in the mixing process. Coke, which is actually a form of fuel produced from coal and important for producing ferro silicon Lastly, iron comes from inside the earth in an ore form of iron mining.

These details need to be weighed and measured carefully beforehand, so we have the optimal amount before starting our actual process. After everything is prepared, we combine the elements in a smelter. The furnace acts like a giant oven which is hot enough to melt the initial raw material so we get everything uniformly mixed and turn into the alloy we are looking for.

Nowadays with the advancements in tech, ferrosilicon making is relatively easier and faster than it used to be. However, nowadays we have modern methods that make way for more productive production of ferro silicon and they now can be made with less human input. It means that workers are not required to do as much heavy lifting or difficult tasks, and it also keeps them safe.

To make sure the ferro silicon we produce is of high quality, we have implemented special control over every step of its production. This involves monitoring the furnace temperature closely and then verifying chemical composition of raw materials we are using. We also ensure that the finished product is of good standard.

The global Ferro silicon market is expected to witness growth due to high demand for steel production in the coming years. These demands have largely been driven by the burgeoning populations seen across numerous developing nations, and also partially due to ever-present requirement for steel within construction. As more and more people require homes, schools and roads built with high-grade steel products the demand for top-quality steel will only rise.

Technological development and strict monitoring on quality control are the reason making ferro silicon is becoming easier and cost effective. This has made it an attractive option for steel manufacturers across the globe, enabling them to meet production requirements pertaining to various projects within a manageable cost.

Xinda accredited by ISO9001, SGS other certification. We have modern and thorough chemical inspection and analysis equipment tested analytical methods offer an objective guarantee the production of high-quality products. Strict ferro silicon production inspection and control raw materials. Make pre-production, during production and after the final random inspection. We offer third-party SGS, BV, AHK).

Xinda Industrial a professional ferro alloy ferro silicon production, situated a key iron production zone, benefit from unique resource advantage. company covers an area of 30,000 square meters with a registered capital of 10 million RMB. Established over 25 years, company home four submerged arc furnaces as well as 4 refinery furnaces. We have more than 10 years of export experience have earned the trust of clients.

Xinda over 10 years of experience ferro silicon production experienced team that can offer professional products for customers. offer every kind customized, like special requirements, sizes, packing etc. state-of-the-art production equipment together with our secure logistic system, ensures a smooth timely delivery final destination.

Xinda a manufacturer that primarily focused the silicon series like ferrosilicon, calcium silica, ferro silicon magnesium, ferro chrome, high carbon silicon, silica slag, and so on. ferro silicon production stocked approximately five thousand tons. have long-term relationships with many steel mills, distributors in the US internationally. global reach includes more 20 countries including Europe, Japan South Korea India Russia.