Ferrosilicon 75 Is A Metal That Aceros, And Industries Utilize In Various Ways It consists of iron and silicon, in two main parts. This metal is extremely useful for different work and it has good qualities which make it better from other materials.

Around 75% of this is used to produce steel, a material that has high tensile strength and low light transmittance which makes it invaluable in construction and manufacturing. It is also the value most commonly used to produce metal mixtures called alloys. Ferrosilicon 75 is good to use because it has a lot of strength and that means it can handle tons without breaking down or becoming damaged, so people love using this type. It is also an excellent conductor of heat and electricity which means that it has a wide range of applications where these properties ubiquitous.

Ferrosilicon 75 consists of iron and silicon primarily. These two things are the main ingredients of this metal. Along with iron and silicon, the ferrosilicon 75 can also contain minor quantities of other materials including carbon or manganese. This combination of parts can react differently with what is needed across different positions or industries. An example is when the steel being produced does not require as much silicon (but greater balance of iron) in which ferrosilicon 75 may have a % chemical species composition with more Fe than Si.

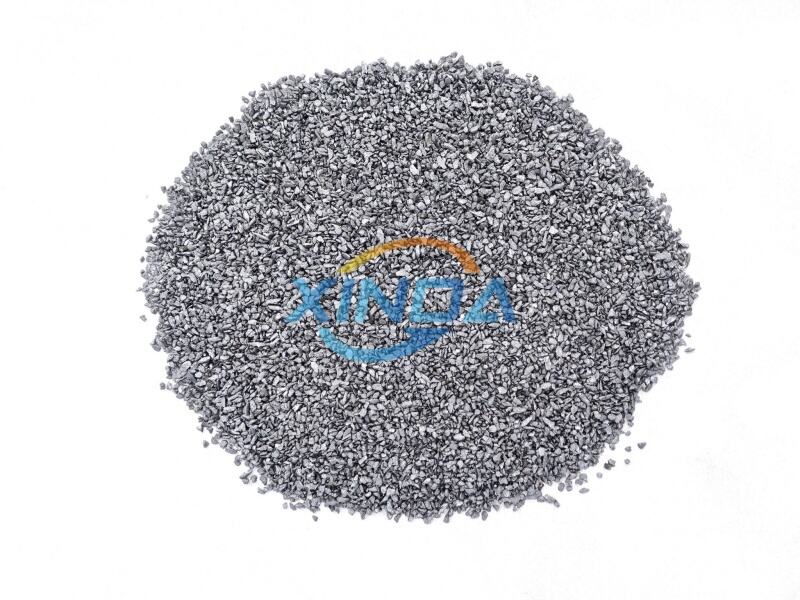

Creating Ferrosilicon 75The production of ferrosilicon uses several critical steps. For starters, raw materials such as molten iron and silicon are melted into a hot furnace. The high temperature aids in their correct amalgamation to a metal alloy. The mixture is then cooled once the materials have combined and melted. Once cool, any unwanted material or impurity is then meticulously separated away to leave only the desired high-quality product. This leaves you with a tough metal which is used in an array of places and applications.

Ferrosilicon 75 is used in several industries as well. In the steel industry, it is an important part of removing oxygen from molten steel that otherwise would oxidize, thus making poorly performance or rear full product. Ferrosilicon 75 makes the steel strong and does not let it be broken because it is brutally hard without any oxygen. It is a key to producing the aluminum alloys needed for automotive and aircraft parts. Moreover, in the making of strong concrete used to construction works for instance as bridges and skyscrapers (to name a few); ferrosilicon 75 is efficiently utilised.

The process resulting in good-quality steel : 1,FERROSILICON 75 is a vital_spell ingredient. During the making of steel there are instances where oxygen can infiltrate into that batch leading to issues, those problems entices what we call impurity. These are grains and are also impurities which can reduce the strength of steel in use, namely for construction applications. This is where ferrosilicon 75 comes into play to remove the oxygen from the steel mixture. This results in the steel being not only stronger, but a higher quality that can be used for many different applications.

Using ferrosilicon 75 in various industries has both advantages and disadvantages. It does have the significant advantage that it works really well in removing oxygen from steel (great for making good products). It is also moderately low-cost in comparison with other metal combinations so will be a cost-effective choice for many manufacturers. Nevertheless, there are obviously disadvantages. The main drawback of ferrosilicon 75, because this substance is fragile and therefore you have to be careful with it. Moreover, heating: it is hard to work with as well when exposed at very high temperatures.

Xinda Industrial a professional ferro alloy manufacturer, situated a key iron ore production zone, benefit from unique resource advantage. business covers area of 30,000 square meters with registered capital 10 million RMB. Established more than 25 years, company has four sets submerged arc furnaces and 4 sets refining furnaces. have over 10years export experience have ferrosilicon 75 trust its clients.

Xinda accredited by ISO9001, SGS other certification. We have modern and thorough chemical inspection and analysis equipment tested analytical methods offer an objective guarantee the production of high-quality products. Strict ferrosilicon 75 inspection and control raw materials. Make pre-production, during production and after the final random inspection. We offer third-party SGS, BV, AHK).

Xinda is manufacturer is primarily focused on the silicon series, like ferrosilicon, calcium silica ferro silicon magnesium, ferro chrome, high carbon silicone, silicon slag, etc. warehouse holds approximately five thousand tons. have long-term relationships numerous steel mills, distributors, both locally as well as internationally. global reach ferrosilicon 75 more 20 countries, including Europe, Japan South Korea India Russia.

Xinda over 10 years of experience ferrosilicon 75 experienced team that can offer professional products for customers. offer every kind customized, like special requirements, sizes, packing etc. state-of-the-art production equipment together with our secure logistic system, ensures a smooth timely delivery final destination.