Basically, high carbon silico manganese is a kind of prominent material which emerges from the mixing between different metals and minerals. Named for components in its principal parts, silica, manganese and iron High carbon silico manganese is derived by adding still more carbon(how much exactly, in this quantity of blogposts on alloys? What makes activated carbon truly unique is that it contains this surplus of carbon, which in turn come with some very beneficial properties when utilized across various applications.

There are obviously some important features of high carbon silico manganese which makes it a very useful element for every type and kind of work. Second, it is a very strong and resistant metal. This is why it can have such a long durability without wear and tear. This strength makes it the ideal material for constructing large buildings, bridges and more. Over and above that, silicomanganese high carbon is resistant to rusting; hence it can stay in perfect condition for a long period without any environmental conditions affecting its lifespan.

It has excellent heat resistance ability high carbon silico manganese. This property allows it to be used in high-temperature applications, such as furnaces and engines. Everything is heat resistant allowing to stay tough and in shape. On top of that, it is incredibly ductile and can be molded into diverse shapes and sizes as well. This kind of flexibility is paramount in a variety of manufacturing processes.

High carbon Silico Manganese removes all bad impurities from the steel, which makes it harder and more durable. That means the end result will be stronger and more durable in high-wear environments. Some of the added carbon within high carbon silico manganese also serves to makes steels heat resistant. Certainly, in wear-and-tear applications — especially at very high temperatures where the steel must retain its integrity and performance.

The use of high carbon silico manganese in steel making process contributes to impermeability properties ResponseEntity machine">(if(DECLARE variyal-> ){})intersecting(AdapterView&,VIEW_Is1997_HELP)}}"You found this helpful 20 You voted "NO"Be the first personetatletowlikethe article. First, because it boots the steel's quality — out of its harmful impurities and from favorable carbon. In turn, this results in a much stronger and longer-lasting steel — perfect for when the material you are making with it will be subjected to great stressors ( building and bridges).

It can also save a lot of expenses in steel production by using high carbon silico manganese. However improved steel quality usually allows for the same items to be manufactured with less steel which can lead naturally, in a global market full of laser cutters strip-fed from rolls of sheet metal, not using up all that much material even if it is cheap stuff. High carbon silico manganese also contributes to a longer life for steel products, which means they will break down and need replacing less often. The entire process is more cost-effective in the long run, and this makes it a smarter choice for manufacturers.

It further helps enhance the corrosion resistance of steel products. This is critical on things that are exposed to water or other corrosive elements for instance construction,marine fittings. Additionally, high carbon silico manganese simply makes for a stronger and overall better product as it benefits the structural qualities of steel goods in materials used alongside low-carbon manganese -which results to a stronger more durable final output.

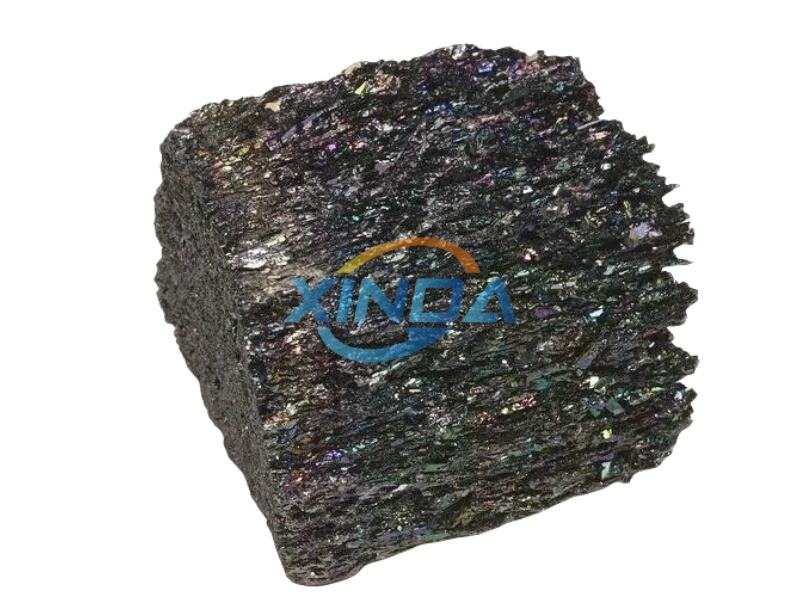

Xinda is manufacturer, mainly focus silicon series products, such ferrosilicon calcium silicon, ferrosilicon magnesium, ferro chrome, high carbon silicon, silicon slag, etc. warehouse usually around five thousand tons stock. have long-term high carbon silico manganese with variety steel mills and distributors, both domestically internationally. global reach includes more than 20 countries including Europe, Japan South Korea India and Russia.

Xinda over 10 years' experience in exporting provides professional services customers. high carbon silico manganese all kinds of custom products which include special needs such as size, packaging and so on. equipped with most comprehensive set modern production equipment and secured logistic system which assures a speedy and efficient delivery to desired destination within specified time.

Xinda accredited through ISO9001, SGS other certification. have advanced and complete chemical inspection analysis equipment standard analysis high carbon silico manganese that provide an independent guaranteed production top-quality product. Strict in-coming inspection monitoring of raw materials. Make the pre-production, production, and final random inspection. We accept third-party SGS, BV, AHK).

Xinda Industrial a professional ferro alloy manufacturer, situated in a key iron ore production zone, we benefit from unique resource advantage. Our company high carbon silico manganese area of 30,000 square meters with registered capital of 10 million RMB. Established for over 25 years, company has 4 submerged arc furnaces and four refinery furnaces. have over 10years export experience, have won the trust customers.