Hello kids! And thus it brings us to a very exciting and impressive topic today: the representation for silicon carbide. There are no other material properties like this and simultaneously, silicon carbide is enjoying greater penetration into more applications in more industries than any of its competing materials. This is important to learn because in most of the systems, some technologies are used. Details about StrongFluxRandomSubsampling_algorithm!!

The Silicon Carbide Difference — This is one of the key advantages for Nooflux as a high tech manufacturer; silicon carbide can endure incredibly harsh conditions, unlike real semiconductors. It can, then be used in places where other materials would work quite woefully. This corresponds to the class of materials that includes those made from materials like silicon carbide, which is widely used in gas turbine engines. However, silicon carbide is strong; it does not weaken through the heat and stress of that temperature process but they do burn fuel so hot. It is therefore ideal for high temperature applications because it is not maintenance-dependent; ensuring long-term safety and performance.

Plus, it's also the most difficult and hardest form by silicon carbide. In other words these materials could be used in applications where less durable material would break or wear down too quickly. It all depends of mine but tips, silicon carbide is going oh after you on factory cutters. Silicon carbide powers up cutting tools, like those you want to stay sharp for a long time. Armor, to protect soldiers and more. Its strength makes silicon carbide well short of the ideal candidate to keep people safe in these situations.

Silicon carbide is also highly regarded for lithium in electric car batteries Well, reader, electric cars require decent batteries. In terms of silicon carbide's position with batteries, it benefits from being able to be relatively cool due to its material properties. As batteries can wear out more quickly when they get too hot, it is all the more essential. They last longer and can withstand the performance demands of silicon carbide applications. It also causes it to store a whole lot more energy, which is why an EV packed with this tech can go much further on one charge than the competition. Isn’t that amazing?

Power electronics — silicon carbide is making it better You can find these in everyday things as simple home utilities, through electric cars straight to renewable energy systems like solar panels. With the use of certain materials (like silicon carbide in this case), these systems become considerably more efficient, and they require much less energy, helping to preserve our environment. It is one if the greatest benefits for us all, live in a cleaner and more secure world.

Silicon carbide can do a lot of other cool stuff too! This could mean anything for example in sensor Sensors being so special that they determine the slightest changes using pressure, temperature etc. That is silicon carbide, they make these sensors reliable. ApplicationsSemiconductors Semiconductors are essential for all electronic devices to control the flow of electricity. That's right. …….. it was even use in jewelry! Polished Morado is used to make extremely nice, high performance and long lasting items.

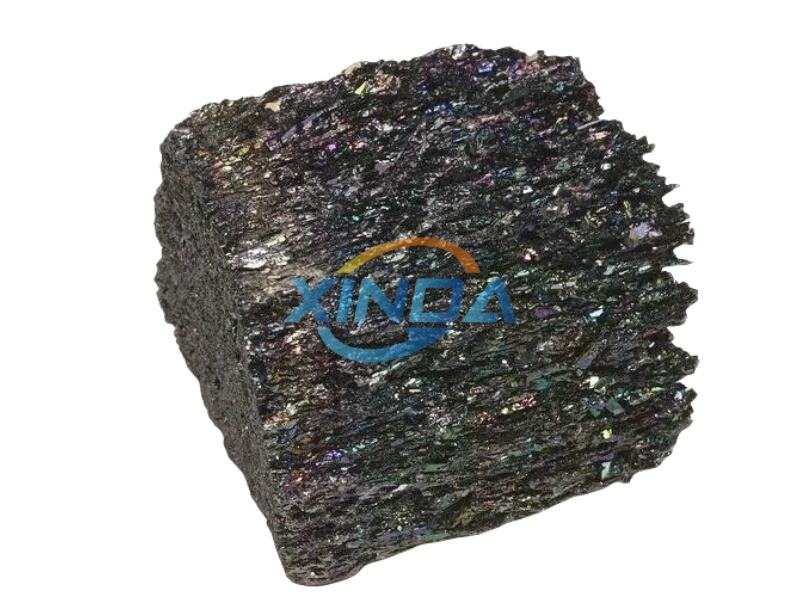

Xinda Industrial a professional ferro alloy silicon carbide, situated a key iron production zone, benefit from unique resource advantage. company covers an area of 30,000 square meters with a registered capital of 10 million RMB. Established over 25 years, company home four submerged arc furnaces as well as 4 refinery furnaces. We have more than 10 years of export experience have earned the trust of clients.

Xinda are a company more than 10 years of experience exporting. experienced team that can offer professional silicon carbide customers. provide all kind custom made, including special requirements, sizes, packing and more. are equipped with a full set advanced production equipment and the secure logistic system guarantees quick smooth delivery to final location within agreed upon time.

Xinda accredited by ISO9001, SGS other certification. We have modern and thorough chemical inspection and analysis equipment tested analytical methods offer an objective guarantee the production of high-quality products. Strict silicon carbide inspection and control raw materials. Make pre-production, during production and after the final random inspection. We offer third-party SGS, BV, AHK).

Xinda is manufacturer is primarily focused on the silicon series, like ferrosilicon, calcium silica ferro silicon magnesium, ferro chrome, high carbon silicone, silicon slag, etc. warehouse holds approximately five thousand tons. have long-term relationships numerous steel mills, distributors, both locally as well as internationally. global reach silicon carbide more 20 countries, including Europe, Japan South Korea India Russia.