Silicon carbide prices can be volatile. There are various reasons why this occurs, and learning them is valuable. One big reason: how much of it there is and how much people want to buy. When there’s not enough silicon carbide to satisfy everyone who wants it, the price goes up because more people are trying to buy it. Or in the case of having much silicon carbide, the price may fall due to a lower number of potential buyers.

Then there are other things that can affect price. For instance, during earthquakes or floods in the places where silicon carbide is made, it can affect how much of the material is produced. Likewise, price shifts can be caused for example if the government is not stable in the countries that produce silicon carbide. This has led to a noticeable price volatility in silicon carbide.

The price of its raw materials are also subject to fluctuation, which translates into the final cost of silicon carbide. When silicon dioxide or petroleum coke rise in price, silicon carbide departs as well. similar to how the price of a cake increases with its ingredients. Q — Why is silicon carbide so expensive? So these raw materials are key to understanding the costs of each.

The price to produce silicon carbide is affected by a number of factors. For instance, the workers' wages can determine the costs of producing. An increase in labor costs can also affect the price of silicon carbide. And if the cost of energy increases as well, then that makes it more expensive to produce. All these various cost enter the picture before you have your final price for silicon carbide.

In these areas, the demand for silicon carbide is growing steadily as more and more industries turn out all kinds of gadgets: automotive applications, electronics. Silicon carbide is useful for electronics because it can withstand a high amount of heat without breaking down and does not lose energy, making it very efficient. That is the reason it is commonly used in devices, for example, mobile and PC.

But silicon carbide is recognized for its higher performance and also more robust durability. This indicates that despite being more expensive per kg compared to alternatives materials, in the long term it is a better option as it provides other benefits. Sometimes, paying a little more for better material will save you money in the long run because it lasts longer and works better.

Companies are constantly exploring ways to improve silicon carbide and lower production costs. They are trying to refine their methods of generating it, and do so more efficiently. This implies that they are seeking new technologies and techniques to enable them to produce silicon carbide more quickly, while also decreasing the expense of their production.

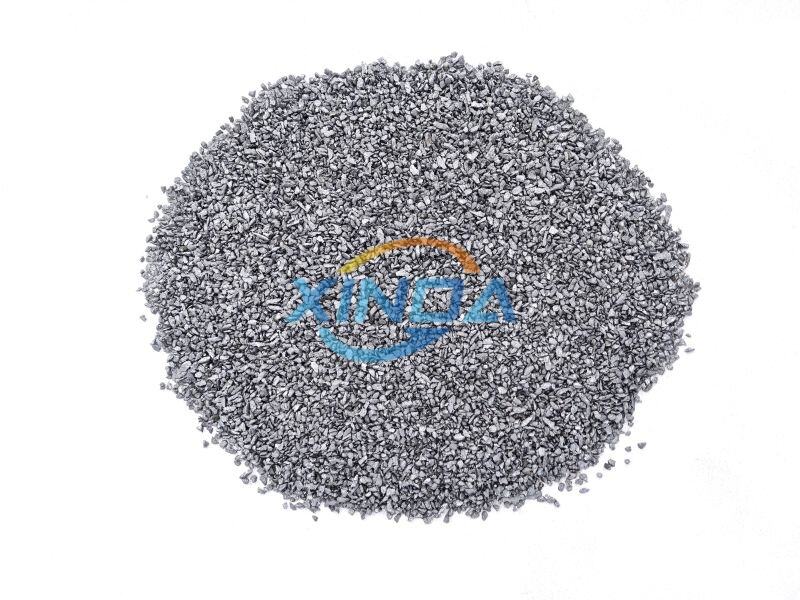

Xinda a manufacturer, mainly focus on silicon series items, including ferrosilicon. calcium silicon, ferro silicon magnesium, high carbon silicon, silicon slag, etc. warehouse normally has about 5,000 tons inventory. silicon carbide cost per kg long-term relationships with numerous steel mills distributors both domestically as well overseas. Covering more than 20 countries regions all across globe including Europe, Japan, South Korea, India, and Russia.

Xinda Industrial a professional ferro alloy silicon carbide cost per kg, situated a key iron production zone, benefit from unique resource advantage. company covers an area of 30,000 square meters with a registered capital of 10 million RMB. Established over 25 years, company home four submerged arc furnaces as well as 4 refinery furnaces. We have more than 10 years of export experience have earned the trust of clients.

Xinda over 10 years' experience in exporting an experienced team who provide high-quality series customers. provide all types of customized products, including requirements, sizes, packing, etc. silicon carbide cost per kg production equipment, together with safe logistic system guarantees a quick and efficient delivery your final destination.

Xinda accredited through ISO9001, SGS other certification. have advanced and complete chemical inspection analysis equipment standard analysis silicon carbide cost per kg that provide an independent guaranteed production top-quality product. Strict in-coming inspection monitoring of raw materials. Make the pre-production, production, and final random inspection. We accept third-party SGS, BV, AHK).