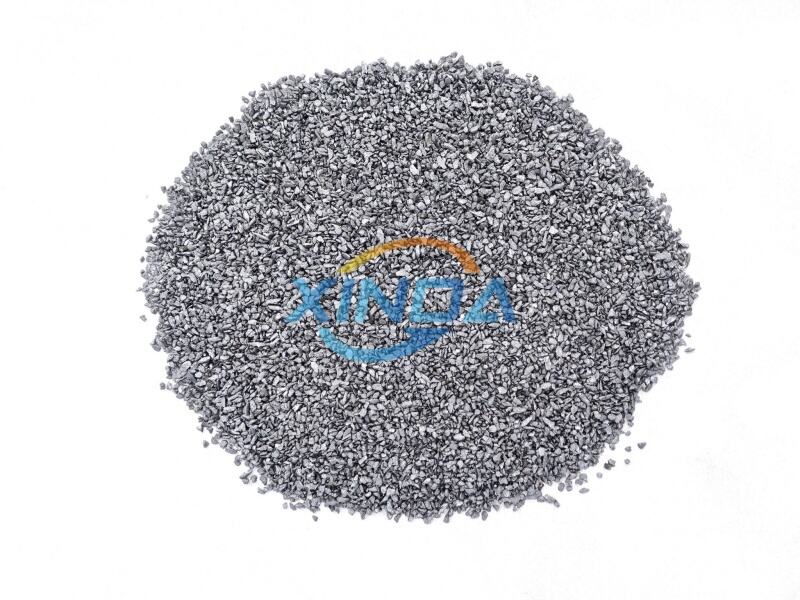

Silicon metal is an essential material in various industries. And finally, Xinda is a business that produces silicon metal, and they contribute to the next great advancement in the world. Let’s discover how silicon metal is produced, why it’s necessary and how it may impact the environment.

Silicon metal is produced through the reaction of carbon materials and silicon dioxide to form silicon and carbon monoxide. This process begins with silica, which is found in sand and rocks. Silica is heated to great temperatures in a furnace with carbon. This underway-process results in a reaction which removes silicon from oxygen in silica to produce silicon metal.

English silicon is introduced in many trades. Silicon is most commonly used in electronics. It can be used to create computer chips, solar panels and other electronic devices. We would not have quite so many technologies we depend on every day.

Silicon is also employed in construction in the form of bricks and concrete, which are stronger as a result. In automobiles, silicon is used in tires and brake pads. Even makeup and skincare products contain silicon.

There’s more demand for silicon metal as more industries are finding uses for it. China is the largest silicon metal producer, followed by Norway, Russia and Brazil. The United States also consumes much silicon metal.

Source: Silicon metal is present in a variety of sectors including the automotive, electronics, construction and the health care industry. The demand will only continue to increase as new technologies that rely on silicon emerge.

The production of silicon metal has come a long way from foundry to factory, and new technologies to refine it promise to make that the case even further. Companies like Xinda are working on fresh methods to make silicon that consume less energy and emit fewer greenhouse gases. They are also working on recycling of silicon metal to minimize waste.

Xinda over 10 years' experience in exporting an experienced team who provide high-quality series customers. provide all types of customized products, including requirements, sizes, packing, etc. silicon metal manufacturer production equipment, together with safe logistic system guarantees a quick and efficient delivery your final destination.

Xinda manufacturer focuses mainly silicon series, such as ferrosilicon calcium silica, ferro silicon magnesium, ferro chrome, high carbon silica, silicon slag. warehouse holds approximately 5,000 tons. have long-term silicon metal manufacturer several steel mills, distributors, both locally as well as overseas. global reach extends to more than 20 countries, which includes Europe, Japan South Korea India Russia.

Xinda certified by ISO9001, SGS and other certification. have advanced and silicon metal manufacturer chemical inspection analysis equipment, and standardized analysis methods provide an assurance objective production top-quality product. Strict inspection and control the incoming flow raw materials. Make pre-production, production, final random inspection. accept third-party SGS, BV, AHK).

Xinda Industrial a professional ferro alloy manufacturer, situated a key iron ore production silicon metal manufacturer, benefit from unique resource advantage. Our company occupies total surface 30,000 square meters with registered capital 10 million RMB. Established more than 25 years and has four submerged-arc furnaces and four sets refinement furnaces. We have gained the trust our clients during past ten years of exporting.