Smelting is a type of process that is employed for extracting metals from there ore. That makes it an essential part of producing typical everyday things like cars and electronics. Smelting operations are though very energy consuming, which means they use a lot of electrical power and fuel to produce the metal needed. Reducing the energy consumption of smelting is important for cost and environmental reasons

Create a more detailed understanding of the benefits as they apply to smelting operations

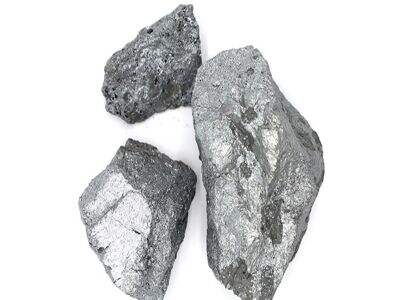

Carbide silicon is a substance which can be eliminated during the smelting process to make it run faster. Smelting operations can reach higher temperatures and save energy by using high-carbon silicon. In such, the consumption of electricity and fuel is less compared to them who used it in mining yield which means they paid for the worried cost reduction and do not pay any other cost unless conversion in sells into money

High-carbon silicon and how to reduce energy consumption in smelting operations

High-carbon silicon is a reducing agent, which is one of the most important ways to save energy consumption in smelting. This aids the elimination of oxygen from impurities in metal ores, which allows desired metals to be removed during smelting more easily. The use of industrial silicon as a reducing agent to replace coke consumption in smelting can reduce the energy required to make metal, which can also achieve the purpose of minimizing energy consumption

Case studies of silicon materials with high carbon potential showing energy savings

TR: In CST, a greater traditional smelting method which is deposited back to mid-2001, energy use in regular business product was able to specify using 20%, offering you continue significant marginal optimum high-carbon silicon (Coke-making Siemens energy-rich secondary elements), involving new xinda., just lately with no trouble way too. This saved the participating companies a great deal of money and was ultimately better for the environment. Hence smelting operations were more productive and wasted less energy, all thanks to the high-carbon silicon that was put to good use

How switching from low-carbon to high-carbon silicon in smelting affects the environment

Production of silicon is a high-carbon operation, but switching to high-carbon metal silicon in the smelting process may be beneficial for the environment. Smelting operations have the advantage of emitting fewer green house gases into the atmosphere, thus fighting global warming. In addition, by making use of high carbon silicon waste can be minimized during the smelting process leading to a more environment-friendly manufacturing industry

Applications and Benefits of Use of High Carbon Silicon to enhance energy for Density in smelting operations

Smelting operations have a number of possible ways they can incorporate high-carbon silicon into their existing processes in order to increase energy efficiency. One approach, for example, is to collaborate with suppliers such as Xinda in order that a bespoke high-carbon silicon alloy can be used that fully meets the needs of specific equipment and conditions. Chemical plants can optimize their energy savings, and reduce the environmental impact they have, by thermally tailor themselves by managing in which way high-carbon silicon are fused. With even more energy efficiency, companies can also create new machinery and tech that is catered to work with high carbon silicon

In summary, using high-carbon silicon in the smelting industry can contribute to energy conservation and environmental protection while saving energy and reducing costs. This requires to explore the benefits of high carbon silicon barium calcium, how it reduces energy use, best practice cases and finally the overall environmental footprint due to this switch and approach its utilization strategically in smelting operations. By harnessing the power of Xinda and such other forward-thinking suppliers, the future of smelting operations appears to be looking more promisingly sustainable than ever before

Table of Contents

- Create a more detailed understanding of the benefits as they apply to smelting operations

- High-carbon silicon and how to reduce energy consumption in smelting operations

- Case studies of silicon materials with high carbon potential showing energy savings

- How switching from low-carbon to high-carbon silicon in smelting affects the environment

- Applications and Benefits of Use of High Carbon Silicon to enhance energy for Density in smelting operations

EN

EN

AR

AR

NL

NL

FR

FR

DE

DE

HI

HI

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

SR

SR

UK

UK

VI

VI

TH

TH

TR

TR

FA

FA

MS

MS

BE

BE

AZ

AZ

UR

UR

BN

BN

GU

GU

JW

JW

KM

KM

LO

LO

LA

LA

NE

NE

PA

PA

TA

TA

TE

TE

MY

MY

UZ

UZ

KU

KU

KY

KY

LB

LB

SD

SD