We produce calcium silicon in our factory — a unique material. The raw ingredient is largely used for steel, which can be found in many things such as cars, buildings and bridges. It is a multi-step process that requires skilled technicians and machines that can perform the complex task with portability. Execution of each one plays a vital role in order to deliver an outstanding product for our customers.

At the outset we separate different raw materials required for calcium silicon making These materials include sand, charcoal and silicon metal. We carefully consider each of these ingredients and how they balance one another, mixing it all together with great attention. To get this perfect, we use some very complex machines. We need a very precise balance of each if we are to create calcium silicon.

Then, we put the mixture that was created into a large electrical furnace. It heats up to over 2000 degrees Celsius! That’s extremely hot! Chemical reaction occurs inside the furnace due to heat. This decomposition ensures that the silicon and calcium are separated from every other material before they eventually form as CALCIUM SILICON. The entire procedure lasts a couple of hours, and we monitor it to see that everything is going along smoothly. We have to be really cautious during this time that the response is actually occurring as planned.

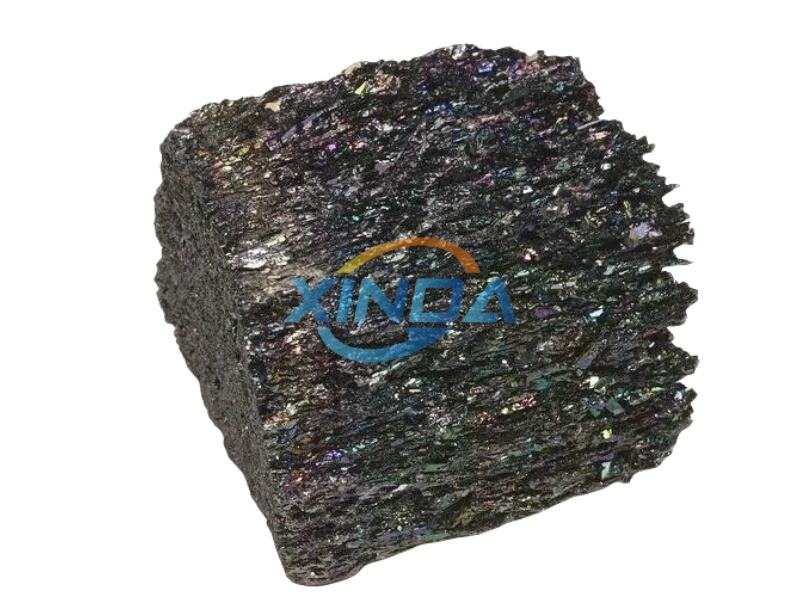

Cool down slowly and broken into different sizes.islesai#SBATCHfillable We do this depending on what our customers need, as different jobs demand varying sizes of calcium silicon. After we have the correct sizes, then comes getting them packed into bags so the product is safe and clean. We pack it and then ready to ship to forward our customer.

Calcium silicon has good use in steel making. It removes the wrong stuff from it, called impurities; and by doing that makes steel much better. This, in turn is very important when improving the quality of steel overall. The steel company also uses calcium silicon to help remove impurities from the steel as it is being made, so that long term issues do not arise. The implication of this is that companies can rely on us for their production needs… end product quality steel.

Our factory is proud to say that it does not rely on gas or coal furnaces, as everything here is electric. Since the implementation of that, pollution has lessened the burden on us as well, decreasing our negative footprint. And though we do not throw away waste materials such as dust and sludge, but instead process them to recycle into useful byproducts.

Our factory have exported a large amount of binary compound inexpensively in short time with calcium silicon. We make a few thousand of tons per year! This is a tremendous amount of product, and we are always searching for better ways to collaborate with Slack teams in order to create even more products that meet our customers' needs.

Xinda Industrial a professional ferro alloy manufacturer, situated in a key iron ore production zone, we benefit from unique resource advantage. Our company calcium silicon factory area of 30,000 square meters with registered capital of 10 million RMB. Established for over 25 years, company has 4 submerged arc furnaces and four refinery furnaces. have over 10years export experience, have won the trust customers.

Xinda has 10 years' experience in exporting provides professional services customers. provide all kinds of custom-made products meet specific requirements, like, size, packaging, more. are equipped with most comprehensive set of modern production equipment as well as the secure logistics system will ensure a smooth speedy delivery at final calcium silicon factory within the stipulated time.

Xinda a manufacturer, mainly focus on silicon series items, including ferrosilicon. calcium silicon, ferro silicon magnesium, high carbon silicon, silicon slag, etc. warehouse normally has about 5,000 tons inventory. calcium silicon factory long-term relationships with numerous steel mills distributors both domestically as well overseas. Covering more than 20 countries regions all across globe including Europe, Japan, South Korea, India, and Russia.

Xinda is accredited through ISO9001, SGS other certification. have latest and most complete chemical inspection analysis equipment tested analytical methods that offer unambiguous guarantee for the production top-quality products. Strict incoming inspection control of raw materials. Make prior to production, during production, and final calcium silicon factory inspection. We support third-party SGS, BV, AHK).