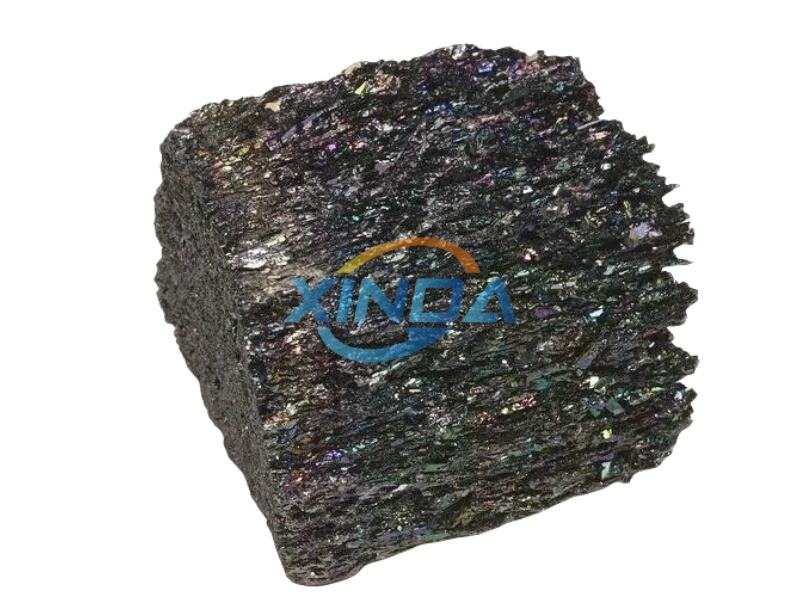

Ferrosilicon is a unique type of alloy, composed of many elements. The combination of these results in a material with exceptional strength that finds application in a range of industries. Ferrosilicon is made by mixing certain key ingredients in just the right proportions. Such components are silicon, carbon, manganese, and so on and they all contribute significantly to the ultimate composition of the alloy.

Ferrosilicon alloy is primarily composed of silicon. It is what makes the alloy strong and durable. Silicon is a key component of a wide variety of different materials because of its contribution to unique properties. In ferrosilicon manufacturer, the silicon is combined with other metals such as carbon and manganese to form a strong alloy that can be used as steel in a number of applications.

Silicon: One special and very important element for composition of Xinda ferrosilicon alloy is silicon. It is why ferrosilicon is so tough and long lasting — this steel-like characteristic is responsible for this. Vastly weaker and less useful, ferrosilicon could not exist without silicon. It is no small matter that silicon is also a major component in other materials, and therefore a particularly important one in the alloy.

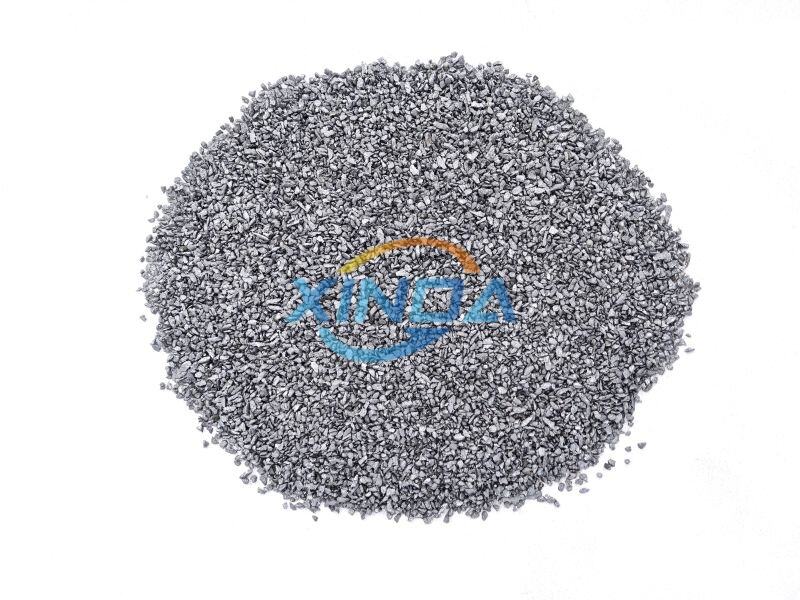

Another significant element to be understood in the composition of Xinda ferrosilicon is carbon. It provides some of the alloy’s hardness and wear resistance. Carbon is also added to enhance the general properties of a basic alloy making it more versatile and use full in tandem of the industries. Besides carbon, other elements, such as manganese, can also have a large influence on the characteristics of ferrosilicon. By precise control of the percentage of each element in the alloy, manufacturers are able to produce ferrosilicon powder with the desired characteristics such as the required content of silicon, iron, aluminium, and carbon.

F1 A potassium gas atmosphere can be employed to reduce such mold contamination, but reduced alloy yield still results, due to losses from the various volatile elements present. – 1- – much Al, At, B, in particular, the degree of tungsten carbide (6 W An even further benefit to the alloy yield is obtained by adding to the desired ferrosilicon composition.

Manganese is one of the other essential elements in the ferrosilicon structure. It influences the strength and hardiness of the alloy, enhancing its usefulness in a range of applications. When mixed together in the perfect proportions, silicon, carbon, and manganese form the perfect Xinda ferrosilicon that its customers need. Manganese is a necessary constituent for the required ferrosilicon composition.

Xinda a manufacturer, mainly focus Ferrosilicon composition series products, such ferrosilicon and calcium silicon, ferro silica magnesium, ferro chrome, high carbon silicon, silicon slag, etc. Our warehouse is usually stocked with around 5,000 tons inventory. have long-term partnerships with numerous steel mills, distributors, both locally as well as overseas. global reach covers more than 20 countries, including Europe, Japan South Korea India and Russia.

Xinda has over 10 Ferrosilicon composition expertise exporting offer expert service our customers. offer all sorts of custom-made products meet specific requirements, like sizes, packaging, more. latest production equipment, our secure logistics system assures efficient and prompt delivery the desired destination.

Xinda Industrial professional ferro alloy manufacturer, situated a key iron ore production zone, benefit from unique resource advantage. company occupies total area of 30,000sqm has the Ferrosilicon composition capital 10 million RMB. Established more than 25 years Our company owns four sets of submerged-arc furnaces as well as four refinement furnaces. have gained the trust of clients during the past ten years of exporting.

Xinda accredited by ISO9001, SGS other certification. We have modern and thorough chemical inspection and analysis equipment tested analytical methods offer an objective guarantee the production of high-quality products. Strict Ferrosilicon composition inspection and control raw materials. Make pre-production, during production and after the final random inspection. We offer third-party SGS, BV, AHK).