کاربورو نڈم قوی ہے اور اس کی تیزی کھو نہیں جاتی جب وہ بہت زیادہ درجہ حرارت پر کام کرتا ہے۔ اگر آپ کسی کارخانے میں کام کر رہے ہیں جہاں بہت زیادہ درجہ حرارت کو تحمل کرنا پڑتا ہے تو یہ فلز بہت اچھا ہے۔ کاربورو نڈم کو فرنیس، کلن اور مختلف گدgets کے پیدا کنندگان نے اکثر پہلے ہی اعلیٰ عملیات کے لیے استعمال کیا۔ یہ ماشینیں ان پر کاربورو نڈم استعمال کرتے ہوئے بہت آسانی اور حفاظت سے کام کرسکتی ہیں۔

کاربورنڈم گرما کے نسبت بہت متنوعہ طور پر کام کرتا ہے کیونکہ یہ سخت مواد: سلیکون کارباڈ سے بنایا گیا ہے۔ یہ چیز واقعی مजबوٹ ہے اور زیادہ گرما اور دباؤ سہنے میں قابل ہے۔ یہ گرما منتقل کرنے میں ماہر ہے جس سے مشینوں کو مردنے والی درجہ حرارت برقرار رکھتے ہوئے بہتر طور پر کام کرنے میں مدد ملتی ہے۔ تو مشینیں بہتر کام کرسکتی ہیں اور غیر ضروری گرمی کے بغیر، اس طرح ان کی عمر استعمال کے دوران بڑھ سکتی ہے۔

کاربورنڈم، چاہے بہت میٹھا ہو اور اس لئے آسانی سے خراش نہیں ہوتا۔ یہ بڑا فائدہ ہے کیونکہ یہ چیز کا طویل عرصہ تک وجود ثابت رہنا مضمون کرتا ہے اور جیسے بدلنے کی ضرورت نہیں پड़تی۔ دوسری طرف، اس کو انسانی جسم کی بہت اچھی طاقتیں ہماری طرف سے استعمال کرتے وقت توڑنے کے بغیر تحمل کرنے کی بھی صلاحیت ہے جب کہ اضافی دबاؤ کام کرنے کے لئے استعمال کیا جاتا ہے۔ یہ سب کہتا ہے کہ آلہ اپنی پوری ہیئت کو حفظ کرتے ہوئے مختلف مطلوبہ محیطات میں بہت اچھی طرح سے کام کر سکتا ہے۔

کاربورنڈم کی یہ کم گرمی کی رفتاری کی وجہ سے وہ گرمی کو رکھتا ہے۔ یہ اس کے مشینوں کے قریب ہوتا ہے، موثر طور پر گرمی کو وہاں رکھتا ہے جہاں آپ کو یہ ضرورت ہے۔ اگر آپ اسے زیستیاتی نقطہ نظر سے دیکھنا چاہیں، تو یہ گرمی کی کمی کو ہوا کے ارد گرد گرمی کے عناصر کے دوران روکتا ہے۔ کیونکہ کاربورنڈم گرمی کو پکڑتا ہے، یہ صنعتی عملوں کو گرم رکھنے کے لئے ضروری انرژی کو کم کرتا ہے اور صنعتی عملوں کے زیستیاتی اثر کو کم کرتا ہے۔

کاربورنڈم صنعتی عمل کے طور پر انرژی کو بچانے میں مددگار ہے اس کے بہت سے فوائد کی وجہ سے۔ جیسے کہ میں پہلے کہا تھا، یہ گرما رکھنے میں بہت اچھا ہوتا ہے۔ یہ سیدھا ٹکر کرتا ہے اور اس کو اسی ماشینوں میں استعمال کیا جاسکتا ہے جو اسے لائن کرتی ہیں، انھیں زیادہ کارآمد بناتا ہے۔ اور یہ گرما بازگردان کرتا ہے جس میں ماشینیں آپریشن کرتی ہیں، انھیں اپنی سب سے زیادہ درجے کے گرما پر زیادہ کارآمدی سے چلتی ہیں جبکہ کم انرژی استعمال کرتی ہیں۔

کاربورنڈم的情况 ماحولیاتی آلودگی کو ختم کرنے کے لئے بھی استعمال ہوتا ہے۔ یہ کورشن سے بھی مقاومت کرتا ہے، جو ماحول کو نقصان پہنچانے والے ریلیج اور ڈرائپس کو روکنے میں مدد کرتا ہے۔ یہ خصوصی طور پر صنعتی استعمال کے لئے مفید ہے جب مواد خطرناک ہوتے ہیں۔ علاوہ ازیں، کاربورنڈم فیکٹریوں میں پایے جانے والے شیمیائی مواد سے مقاومت کرتا ہے جو اسے زیادہ ماحول دوست اور ماحول کے لئے کم نقصان دہ بنتا ہے۔

اس کے علاوہ، یہ سیمی کانڈکٹر تصنيع جیسے الیکٹرانکس کے شعبے میں بھی اہم ہے۔ الیکٹرانکس میں یہ اہم ہے کیونکہ اس کی بہت اچھی گرمی کی رفتار ہوتی ہے، جو کئی الیکٹرانکس اپلی کیشن کا اصلی دماغ ہے۔ اس کے علاوہ، یہ بہت زیادہ ولٹیج اور مشابہ تکلیف کے خلاف بہت مضبوط ہے جو سلیکون کارائید چیپ کو مختلف الیکٹرانکس دستیاب کرنے کے لیے استعمال کرنے میں مدد کرتی ہے۔ یہی وجہ ہے کہ کاربورو نڈم مدرن ٹیکنالوجی میں بھی اتنا اہم ہے: یہ باہری گرما کے شرائط میں کام کرتا ہے۔

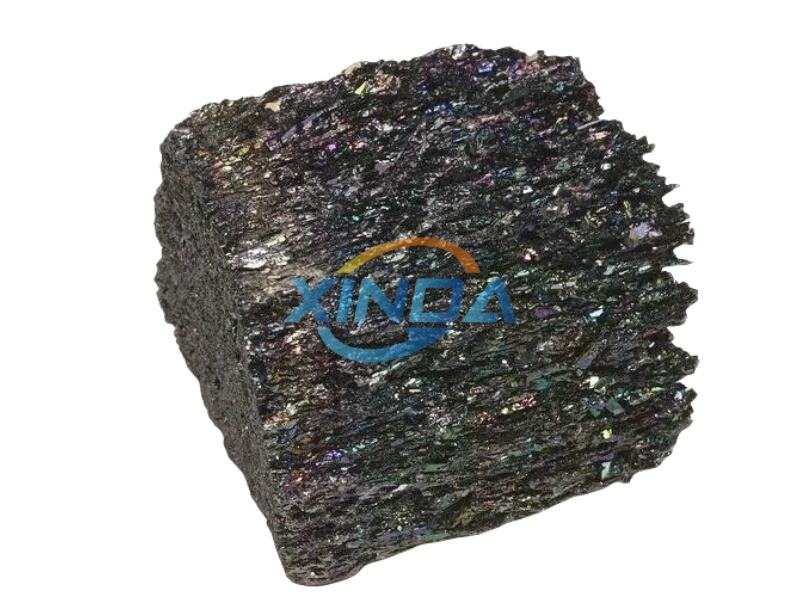

شِنڈا آئی ایس او 9001، ایس جی ایس اور دیگر تصدیق شدہ اداروں کے ذریعے منظور شدہ ہے۔ اس کے پاس کیمیائی معائنہ اور تجزیہ کے لیے سب سے جدید جامع آلات موجود ہیں، جو معیاری تجزیاتی طریقوں کے ذریعے غیر مبہم کاربورنڈم ریفریکٹری کی پیداوار کو یقینی بناتے ہیں جو اعلیٰ درجے کی مصنوعات کی تیاری کے لیے استعمال ہوتا ہے۔ خام مال کے داخلی بہاؤ کا سخت معائنہ اور کنٹرول کیا جاتا ہے۔ تیاری سے پہلے، تیاری کے دوران اور حتمی تصادفی معائنہ کیا جاتا ہے۔ ہم تیسرے فریق کے معائنہ اداروں جیسے ایس جی ایس، بی وی اور اے ایچ کے کام کی حمایت کرتے ہیں۔

شِنڈا ایک صنعت کار ہے جو بنیادی طور پر سلیکون سیریز کی اشیاء پر مرکوز ہے، جن میں فیرو سلیکون، کیلشیم سلیکون، فیرو سلیکون میگنیشیم، ہائی کاربن سلیکون، سلیکون سلاگ وغیرہ شامل ہیں۔ اس کے گودام میں عام طور پر تقریباً 5,000 ٹن کا انوینٹری موجود رہتا ہے۔ کاربورنڈم ریفریکٹری کے لیے شِنڈا کے متعدد سٹیل ملز اور ڈسٹری بیوٹرز کے ساتھ گھریلو اور بین الاقوامی سطح پر طویل المدتی تعلقات قائم ہیں۔ یہ تعلقات دنیا بھر کے 20 سے زائد ممالک اور علاقوں تک پھیلے ہوئے ہیں، جن میں یورپ، جاپان، جنوبی کوریا، بھارت اور روس شامل ہیں۔

شِنڈا انڈسٹریل، پیشہ ورانہ فیرو ایلائے کے سازاں، جو کہ اہم آئرن آر کے پیداواری علاقے میں واقع ہیں، منفرد وسائل کے فائدے حاصل کرتے ہیں۔ ہماری کمپنی کا کل رقبہ 30,000 مربع میٹر ہے اور رجسٹرڈ کیپٹل 10 ملین RMB ہے۔ 25 سال سے زائد عرصہ قبل قائم کی گئی، جس کے پاس چار کاربورنڈم ریفریکٹری آرک فرنیس اور چار ریفائنمنٹ فرنیس ہیں۔ ہم نے برآمدات کے دس سالہ دوران اپنے صارفین کا اعتماد حاصل کیا ہے۔

شِنڈا کو برآمدات میں 10 سال کا تجربہ حاصل ہے اور یہ صارفین کو پیشہ ورانہ خدمات فراہم کرتی ہے۔ ہم تمام اقسام کے مخصوص ضروریات کے مطابق بنائے گئے مصنوعات، جیسے سائز، پیکیجنگ وغیرہ، فراہم کرتے ہیں۔ ہماری تیاری کے لیے جدید ترین تیاری کے آلات کا سب سے مکمل سیٹ اور محفوظ لاگسٹکس نظام موجود ہے، جو مقررہ وقت کے اندر آخری کاربورنڈم ریفریکٹری کی ہموار اور تیز ترسیل کو یقینی بناتا ہے۔