Ferroalloys are also important when it comes to creating things with metal such as cars, machines, or tools. Ferroalloys are special combinations of iron and other metals that help make these items strong and durable. Ever heard of processing ferroalloys to make them better? Yes, that’s what tailor-making ferroalloys is!

OEM is short for "Original Equipment Manufacturer. " This is because the company producing the hardware or machinery requires a specific type of ferroalloy to make the product in the right way. Xinda understands this and this is where Xinda customized ferroalloy solutions work for OEMs. It makes sure that the final product is the best possible by adjusting the ferroalloys to what the OEMs want.

Ferroalloys can be combined in different ratios to produce special properties that make products function better. Xinda is really good at blending these special mixes that enhance strength and longevity. By combining those metals in the right proportions, Xinda guarantees that the products perform better and have a longer service life, and so have more value for the people who use them.

Efficiency is doing thing the right way. Efficiency is extremely important when processing ferroalloys. Custom Ferroalloys at Xinda Xinda's custom ferroalloys make manufacturers more efficient by giving them exactly what they want. Proper use of the right ferroalloys are likely going to allow those in heat treating to produce a better end product faster and cheaper, and in this day and age, time and the bottom line mean everything.

OEM standards are akin to guidelines that manufacturers must adhere to in order to make their goods safe and reliable. Xinda makes it easier for the manufacturers to achieve these vital standards and our tailor-made ferroalloy solutions comply with all relevant rules. With the use of premium ferroalloys that match the OEM, manufacturers can rest assured that their ferrocomponents will be up to standard.

Product integration is about ensuring that all the pieces in a product fit well together. By producing ferroalloys to suit, Xinda makes it happen that the metal parts fit together well and work properly. This has the effect of making the products more robust and dependable. Through the use of specialty ferroalloys, manufacturers can produce products that are seamless, energy efficient and will stand the test of time.

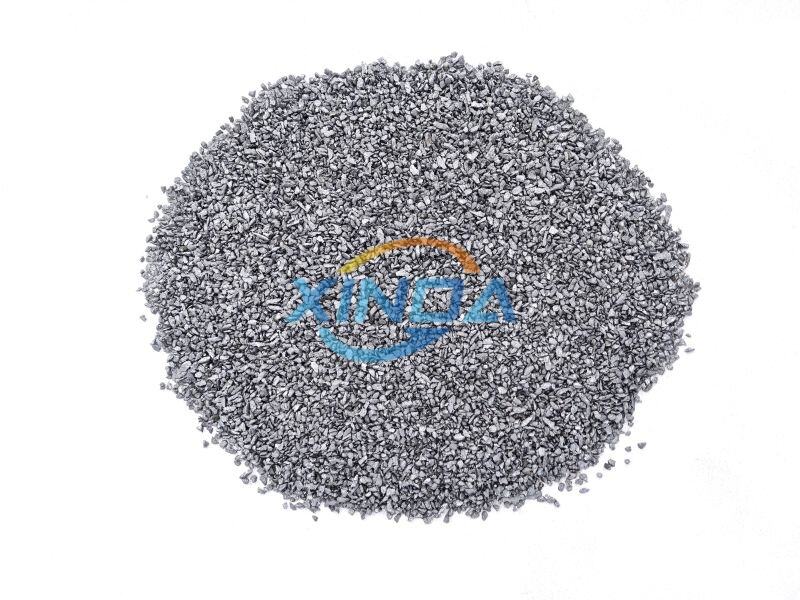

Xinda a manufacturer, mainly focus OEM ferroalloy customization series products, such ferrosilicon and calcium silicon, ferro silica magnesium, ferro chrome, high carbon silicon, silicon slag, etc. Our warehouse is usually stocked with around 5,000 tons inventory. have long-term partnerships with numerous steel mills, distributors, both locally as well as overseas. global reach covers more than 20 countries, including Europe, Japan South Korea India and Russia.

Xinda certified by ISO9001, SGS other OEM ferroalloy customization. have advanced and complete chemical inspection analysis equipment tested analytical methods that offer an independent guarantee the production top-quality products. Strict Inspection and control raw materials. Make prior to production, during production as well as final random inspection. We support third-party SGS, BV, AHK).

Xinda has over 10 OEM ferroalloy customization expertise exporting offer expert service our customers. offer all sorts of custom-made products meet specific requirements, like sizes, packaging, more. latest production equipment, our secure logistics system assures efficient and prompt delivery the desired destination.

Xinda Industrial a professional ferro alloy manufacturer, situated a key iron ore production OEM ferroalloy customization, benefit from unique resource advantage. Our company occupies total surface 30,000 square meters with registered capital 10 million RMB. Established more than 25 years and has four submerged-arc furnaces and four sets refinement furnaces. We have gained the trust our clients during past ten years of exporting.