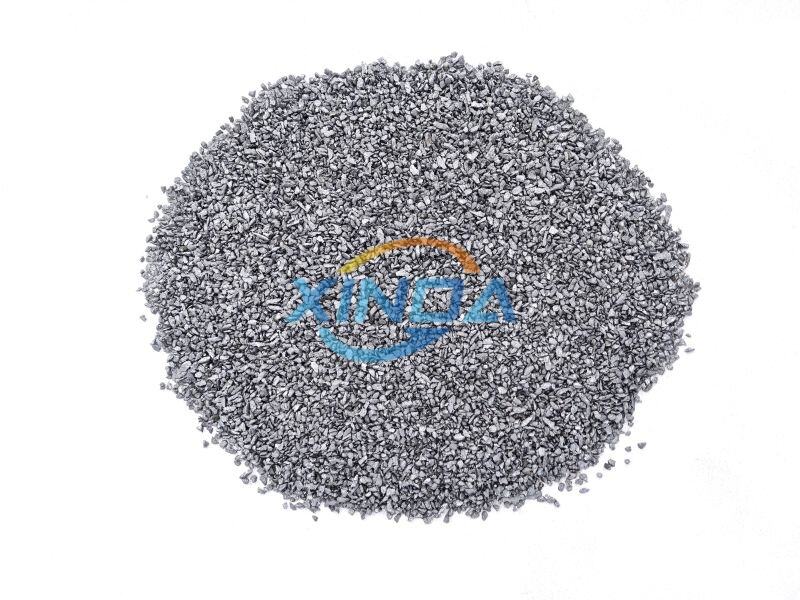

SiC alloy is a new type of material with wide application range. It is composed of silicon and carbon. Those 2 things combined give beryllium some kind of awesome super powers that make it useful in loads of different industries. SiC alloys, it is changing technology. Below we dig into where you can use it, why is strong and light weight and a good option appealing when the going gets tough.

There is a special property of the SiC alloy that distinguishes it from all others. In the first place, it is very tough and strong so that very little damage can occur even if a lot of force or strain is exerted on them. In addition, it is light-weighted so for the applications where weight reduction plays a pivotal role, this DBS foam becomes perfect. It is not ideal for, say, airplanes or fast cars where your weight matters but it weighs less than elastomer. It also has an advantage that it does not easily wear. It is designed to repel rust and corrosion so you will enjoy long-term benefits of not repairing or replacing for a very long time. As a result this is the preferred choice for many engineers and manufacturers.

So now, with technology that once seemed irretrievably lost SiC alloy is coming back to the tech game. It has some of the greatest effects on electronic parts such as microchips. These components are thus cheaper and more reliable, courtesy of SiC alloy. More people can afford to use, and therefore benefit from our technologies — a key component of making technology accessible for all. In addition, SiC alloy enhances the performance and efficiency of electronic devices. Such efficiency is essential in today-based world where we are much dependent on machines and gadgets for quite many things.

SiC alloy is one of the biggest advantages because they are stronger and weigh less than traditional materials such as steel or aluminum. It can be less material to take more strength because it is so strong than other materials for structures or products. Not only does this save weight, but it also improves efficiency. In vehicles, for instance, SiC alloy could help cars consume less fuel while maintaining safety and strength. SiC alloy also sees its longevity benefits with a longer shelf life than many other materials, so less maintenance is required down the road. That is a very positive development for both manufacturers to consumers as it will decrease price and repairs needed.

SiC alloy is expected to be widely used in aviation, automotive and other fields. This makes, among many other things planes and cars lighter and stronger so that they may perform better. A lighter vehicle will go faster and further on less fuel, which is better for the environment as well as your wallet. The SiC alloy, meanwhile is also highly applicable to higher temperature and extreme service conditions of many kinds. This makes it perfect for heavy-duty applications like rocket engines and high power racing vehicles. This makes it a good material for many high-tech applications, where its performance under pressure is in use.

SiC alloy is a wise pick for heavy-duty work and environments, too. Amidst being such a quality product, it is also immensely strong and tough that allows the tents to stay in shape for an extremely long time without having to replace/repair them frequently. It is the best tool for use in heavy duty industry such as offshore oil rigs and manufacturing factories due to its high degree of corrosion resistance and wear. These places generally have extreme environments, and the material that can survive such conditions are necessary for safety as well as efficiency.

Xinda Industrial a professional ferro alloy manufacturer, situated in a key iron ore production zone, we benefit from unique resource advantage. company covers space of 30,000 sq meters with registered capital of 10 million RMB. Established for over 25 years, company has 4 submerged arc furnaces and four refineries Si C alloy. have over 10years export experience, we have won the trust of clients.

Xinda has more than ten years' experience exporting. team experts who can provide professional services customers. We offer every kind custom-made, such special requirements, sizes, packing and so on. are equipped with a range modern production equipment, well as the security-secured logistics system that assures a speedy efficient Si C alloy to the destination within the stipulated time.

Xinda certified by ISO9001, SGS and other certification. have latest most complete equipment chemical analysis and inspection and standardized analysis methods provided an Si C alloy guaranteed production top-quality product. Strict Inspection and control of raw materials. Make an inspection prior to production, during manufacturing as well final random inspection. We support third-party SGS, BV, AHK).

Xinda a manufacturer, mainly focus Si C alloy series products, such ferrosilicon and calcium silicon, ferro silica magnesium, ferro chrome, high carbon silicon, silicon slag, etc. Our warehouse is usually stocked with around 5,000 tons inventory. have long-term partnerships with numerous steel mills, distributors, both locally as well as overseas. global reach covers more than 20 countries, including Europe, Japan South Korea India and Russia.