It is highly rigid in the form of silicon carbide. It also has a broad range of applications in things we encounter every day — such as car brakes that help bring vehicles to a safe stop, cutting tools that help shape what we use and buy, and in the rockets that take humans and manmade items to space! Silicon carbide is so useful and desirable for many products that many companies have an interest in obtaining it in large quantities. This results in an either up or down scenario for price. (These are when Many People Want to Buy Silicon Carbide, the Price Usually Increases.) But if less people are interested on buying it the price will probably go down.

Supply and Demand Just like every other market, supply and demand are a significant factor when it comes to pricing. If a lot of companies are interested in purchasing silicon carbide but there’s not enough to go around, the price is going to rise. And that’s because companies are prepared to spend more to secure the silicon carbide that they require. But if there is too much silicon carbide — and not enough companies eager to buy it — the price will fall.

Production Costs: The manufacturing of silicon carbide occurs in high-tech manufacturing plants, and quiet distinctly maintains certain operational costs. At times, the factories may have to deploy dearer raw materials or contend with soaring energy and labour costs. In this case, the price of silicon carbide can go up since the firms must recover these additional costs.

Competition: Similarly, the number of companies that do silicon carbide also impacts price. When numerous companies are competing to sell silicon carbide, they can drive their prices down to gain more customers. Silicon carbide buyers benefit from the constant competition that translates into favors rabatt, thus lowering the general price.

The price of silicon carbide can also be affected by what is going on in other parts of the world. Let us say, for instance, that a major Chinese company begins incorporating a large amount of silicon carbide in their products. If they suddenly require a lot more than usual, it can cause the price to increase. That will be less silicon carbide for other companies to buy. I’m also curious about the potential impact of global events (e.g., changes to trade agreements; changes to economic conditions) on prices.

Technology changes: Sometimes, new technologies are invented which make it possible to use less silicon carbide in products. When this happens, this allows the demand for silicon carbide to diminish and thus a lower price. It is important for companies to follow technology trends to anticipate the impact they will have in the market.

Volume Discounts: Certain businesses may offer discounts to customers who purchase large volumes of silicon carbide. They may, for example, provide a 10% discount for customers that were purchasing more than 100 pounds of silicon carbide. It also encourages customers to purchase more, and helps the company to sell more quantity of that item.

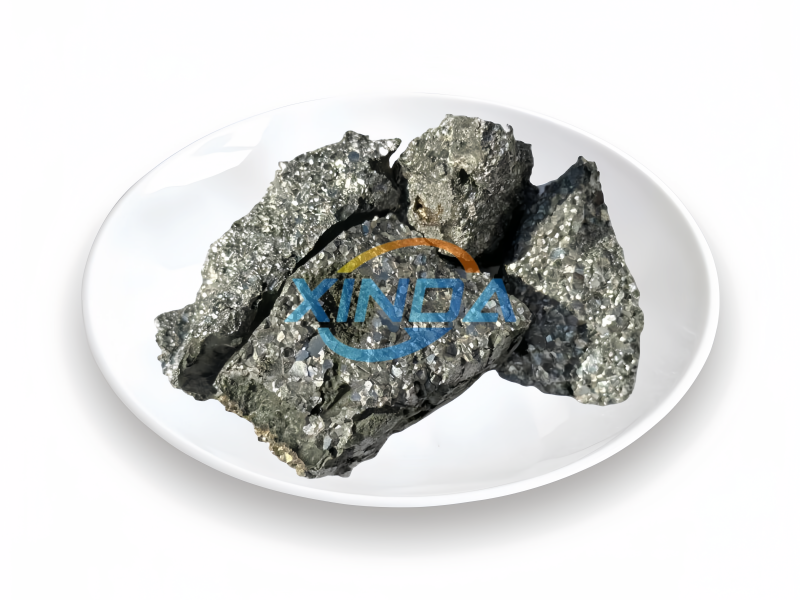

Xinda certified by ISO9001, SGS and other certification. have advanced and silicon carbide price chemical inspection analysis equipment, and standardized analysis methods provide an assurance objective production top-quality product. Strict inspection and control the incoming flow raw materials. Make pre-production, production, final random inspection. accept third-party SGS, BV, AHK).

Xinda Industrial a professional ferro alloy manufacturer, situated a key iron ore production silicon carbide price, benefit from unique resource advantage. Our company occupies total surface 30,000 square meters with registered capital 10 million RMB. Established more than 25 years and has four submerged-arc furnaces and four sets refinement furnaces. We have gained the trust our clients during past ten years of exporting.

Xinda over 10 years expertise in exporting offer expert services to customers. offer a wide range customized products including special requirements sizes, packaging, etc. modern production equipment, along with safe silicon carbide price system assures efficient and prompt delivery to final destination.

Xinda is an established manufacturer. concentrate silicon series items, including ferrosilicon. Calcium silicon, ferro silicon magnesium, high carbon silicon, silicon slagged. warehouse typically stocks around five silicon carbide price tons stock. have long-term agreements numerous steel mills and distributors both locally as well as overseas. Covering more 20 countries regions across the globe which includes Europe, Japan, South Korea, India, Russia.