Melting raw materials in a furnace usually produces silicon from experience. Raw materials to siliconOverall, the process of converting raw material into pure or ultrapure metals and then subsequently on with careful reduction steps like chlorination is accompanied by waste side products. In most cases, one of the by-products is called Slag or Silcon slag. The disposal and management of such by-products can therefore pose a challenge, resulting in more costs. This is why Silcon Slag 70 which can also be called granulated silica fumes comes in handy, it saves costs and for silicon making process makes easier.

Silcon Slag 70 helps capture and minimise the crystallised slag that comes from silicon manufacturing. Even for our environment, it is utmost as we reduce pollution levels and carbon emissions. Silcon Slag 70 allows the waste output from silicon production to be properly and safely disposed of, hence allowing us to keep producing vital materials for many other industries while still looking out for our planet.

Among the various industries, silicon has become an important element and is increasing in demand day by day. But the conventional way to create silicon is pretty bad for Mother Nature: it requires lots of energy and creates considerable waste. More sustainable methods like the use of Silcon Slag 70 will not only increase production and reduce environmental impact, but it also ensures its viability for years to come.

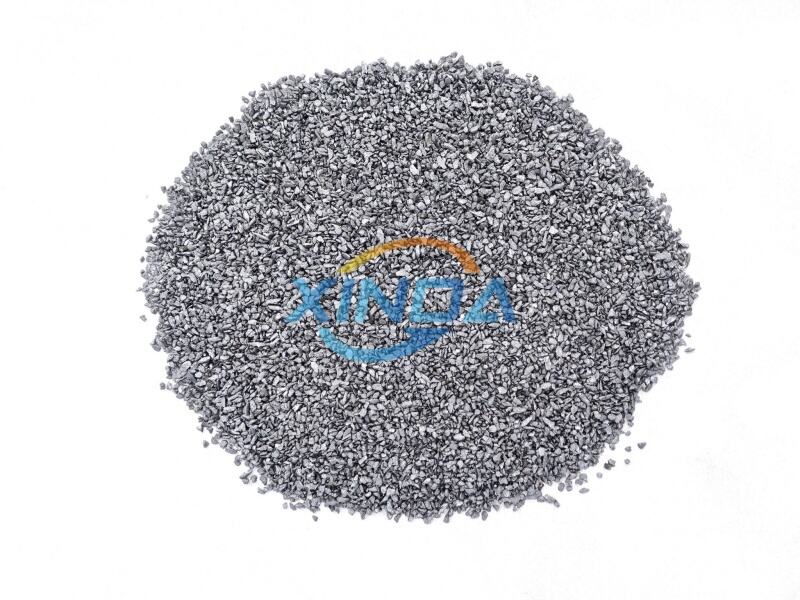

General Information : Silcon Slag 70 is new kind of special products for replacing classic proportions silicon briquette and ferrosilicon in iron making phase, also it can replace recarburizer during the steelmaking production. The use of Silcon Slag 70 helps tackle this, a little helping hand to make the production method more kinder on our planet. By that way, it can help make our future better and avoid unwanted waste.

The product Silcon Slag 70, ideally developed for use in numerous sectors such as iron and steel industries besides a road construction paves the path to VSDK Innovation Solutions LLP vision of green environment. While conventional particles of silica can be highly inefficient, and waste-prone the Silcon Slag 70 is developed by modern means. This means it will operate efficiently and is a better option for producers.

This Is A New Product Which Had Brought Revolution In The Production Of Silicon As Silcon Slag 70. These largest associated concerns relate to high levels of energy consumption and waste that may arise during the manufacturing process. It is also better for the environment as regards the manufacture of iron, building roads and many others.

Silica particles, the traditional type of nanoparticle that was studied previously at RIT, can be especially deactivating and lead to a dramatic byproduct waste impact on our environment. That was until Silcon Slag 70 answered those problems. This should help silicon manufacturers advance the way they manufacture an inherently inefficient, environmentally unfriendly and expensive carbon material.

Xinda over 10 years of experience Silcon Slag 70 experienced team that can offer professional products for customers. offer every kind customized, like special requirements, sizes, packing etc. state-of-the-art production equipment together with our secure logistic system, ensures a smooth timely delivery final destination.

Xinda has been accredited by ISO9001, SGS other Silcon Slag 70. have modern fully equipped inspection analysis equipment, standard methods for in-coming inspection raw materials. Perform random inspections during production, during process then the final inspection.

Xinda Industrial a professional ferro alloy Silcon Slag 70, situated a key iron production zone, benefit from unique resource advantage. company covers an area of 30,000 square meters with a registered capital of 10 million RMB. Established over 25 years, company home four submerged arc furnaces as well as 4 refinery furnaces. We have more than 10 years of export experience have earned the trust of clients.

Xinda is manufacturer, mainly focus silicon series products, such ferrosilicon calcium silicon, ferrosilicon magnesium, ferro chrome, high carbon silicon, silicon slag, etc. warehouse usually around five thousand tons stock. have long-term Silcon Slag 70 with variety steel mills and distributors, both domestically internationally. global reach includes more than 20 countries including Europe, Japan South Korea India and Russia.