Ferro chrome is a vital alloy in a large number of steel industries. It is produced by combining chromium with iron. One of the important things to understand regarding ferrro crome is it's melting point. That’s the temperature at which it melts from a solid to a liquid. Knowing melting points of ferro chrome is vital for utilizing it correctly in factories.

It is interesting to see what influences the melting point of ferro chrome. The melting point can vary depending on how much chromium has been mixed with how pure the chromium is and the details of how it’s made. Understanding these factors raises our ability to select the appropriate grade of ferro chrome for various tasks.

The temperature at which ferro copper is melted at production is crucial. A melting point that is too low could make it incapable of certain uses. If too high, it can be difficult to manage. It can also be used 24/7 including in temperatures of 950c. With correct control of the melting point improvement in ferro chrome function will be ensured.

It is also helpful to compare the melting point of Ferro chrome with the other ferro alloys. It has high melting point to resist corrosion, and is the most versatile because it can work in high-temperature applications thus making it the most common used types of ferroalloys. This is critical in the aerospace, automotive and construction sectors.

There is always an attempt by people to increase the melting point of ferro chrome to perform well in different industries. Designers and engineers continue to seek ways to make ferro chrome even better. Through innovative processes and technologies, they can produce ferro chrome which is stronger, and last longer and is more useful than ever.

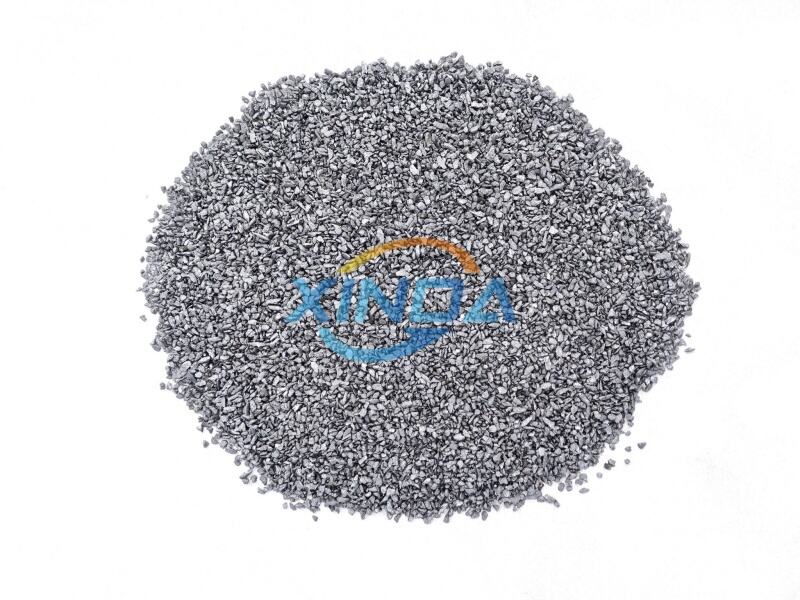

Xinda is manufacturer is primarily focused on the silicon series, like ferrosilicon, calcium silica ferro silicon magnesium, ferro chrome, high carbon silicone, silicon slag, etc. warehouse holds approximately five thousand tons. have long-term relationships numerous steel mills, distributors, both locally as well as internationally. global reach ferro chrome melting point more 20 countries, including Europe, Japan South Korea India Russia.

Xinda certified by ISO9001, SGS and other certification. have advanced and ferro chrome melting point chemical inspection analysis equipment, and standardized analysis methods provide an assurance objective production top-quality product. Strict inspection and control the incoming flow raw materials. Make pre-production, production, final random inspection. accept third-party SGS, BV, AHK).

Xinda Industrial a professional ferro alloy ferro chrome melting point, situated a key iron production zone, benefit from unique resource advantage. company covers an area of 30,000 square meters with a registered capital of 10 million RMB. Established over 25 years, company home four submerged arc furnaces as well as 4 refinery furnaces. We have more than 10 years of export experience have earned the trust of clients.

Xinda has over 10 ferro chrome melting point expertise exporting offer expert service our customers. offer all sorts of custom-made products meet specific requirements, like sizes, packaging, more. latest production equipment, our secure logistics system assures efficient and prompt delivery the desired destination.