Ferro silicon is one of several alloy blends used to produce steel. It is composed of silicon and iron, with small amounts of other elements. It is important to know what ferro silicon is made of so that it will work properly in the process of making steel. This is where testing is important.

The following are serious methods to test feeding ferro silicion. These include X-ray fluorescence (XRF) and other techniques that let curiosity seekers find out how much silicon, iron and other materials are in the mix. Once manufacturers understand what, exactly, is in ferro silicon, they can alter it to create better steel.

It is very important to be careful when you are testing ferro silicon. Even small alterations in what the mix holds may have a significant impact on the steel. For instance, too much silicon can make the steel brittle, while too little can make it weak. By testing carefully, manufacturers can ensure their ferro silicon is perfect for steelmaking.

It cannot be neglected that screening of bad materials is quite vital for maintaining quality in ferro silicon. Noxious ingredients including sulfur, phosphorous and carbon can alter the way the steel behaves and must be kept in check. Sophisticated testing techniques detect and quantify these bad materials. Manufacturers can guarantee their mix meets strict standards by omitting them.

Recent advances in technology have also helped make the testing of ferro silicon more accurate. For example, lasers can enable quick and precise testing of the contents of the mix. It further assists one in interpreting the results of testing more readily as well. These advancements have helped to make production of the ferro silicon better and more precise.

Xinda been accredited with ISO9001, SGS other certifications. We equipped with most advanced complete inspection analysis equipment, ferro silicon chemical analysis methods strict in-coming inspection raw materials. Make random inspections during production, during the process, the final inspection.

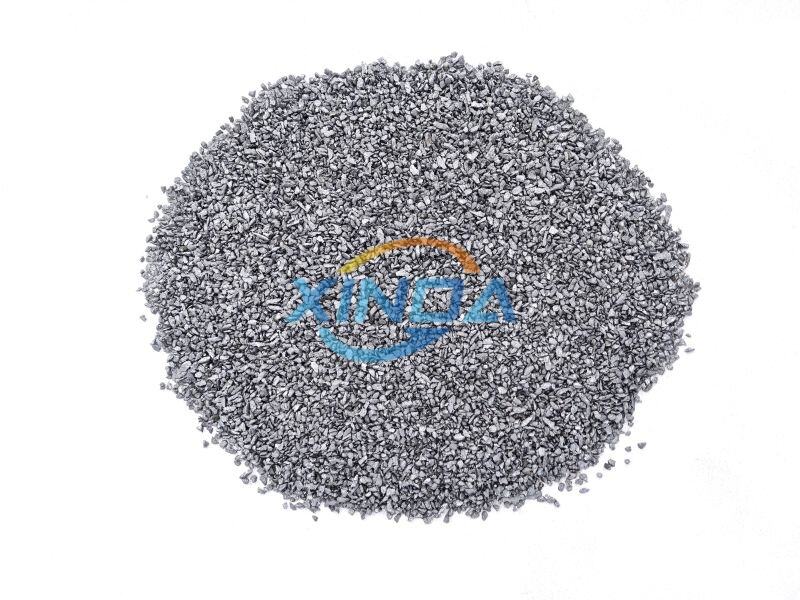

Xinda a manufacturer that primarily focused the silicon series like ferrosilicon, calcium silica, ferro silicon magnesium, ferro chrome, high carbon silicon, silica slag, and so on. ferro silicon chemical analysis stocked approximately five thousand tons. have long-term relationships with many steel mills, distributors in the US internationally. global reach includes more 20 countries including Europe, Japan South Korea India Russia.

Xinda Industrial a professional ferro alloy manufacturer, situated in key iron ore ferro silicon chemical analysis zone, we benefit from unique resource advantage. Our facility covers space 30,000 sq meters with registered capital of 10 million RMB. Established for over 25 years, company home to four submerged arc furnaces four refinery furnaces. have over 10years export experience have earned the trust of its customers.

Xinda over 10 years' experience in exporting an experienced team who provide high-quality series customers. provide all types of customized products, including requirements, sizes, packing, etc. ferro silicon chemical analysis production equipment, together with safe logistic system guarantees a quick and efficient delivery your final destination.