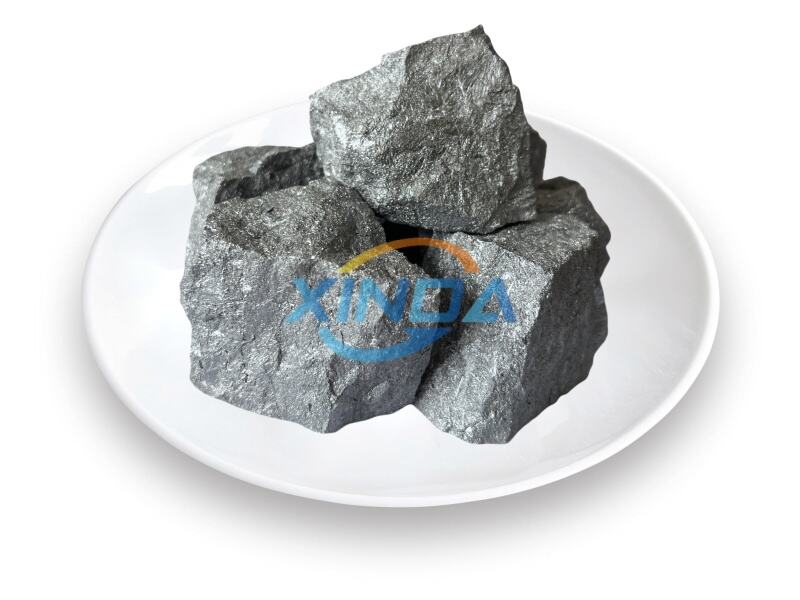

Ferro silicon Ferror Silicon is the combination of two important things: Silicone and Iron. When these two components are combined, a new materials called ferro silicon is created. It is especially necessary and it allows you to create steel, alloys which have greater durability over a long period.

Steel and alloys are produced in a factory which is added with Ferro silicon. Since they are added to the metals, which means that it increases wear resistance and heat treatment properties as well as corrosion. This results in a longer shelf-life of objects made out of these materials and will also be more effective applications. For instance, any vehicle that is made from well-graded steel will never have all of it damaged in a crash.

Then, consider that this bridge must withstand the weight of numerous cars and trucks. What about building a skyscraper upwards that can resist against some of the most powerful wind and occasional earthquakes on earth. These types of jobs are laborious and require highly strong as well as durable materials. The construction materials used can be strengthened through the use of ferro silicon.

It is also mixed with building materials to help them become as strong and durable as possible due to the actual inclusion of some ferrosilicon in it. This is crucial to preventing designer accidents that might cause buildings or bridges not being safe for all users. Through ferro silicon investment, we can alter how things are structured and conceive them better for the future.

Ferro silicon are particles until they have been put to use in factories, but then it makes so much difference in various industries. It is used not only in construction but also electronics and even renewable energy. Ferro silicon industrial growth fulfills the same need but stronger, better materials for more and more products should keep The ferro siilcon industry growing.

People are finding new ways to use these materials and creating all different types of ferro silicon, that it is hard not to want more. As a result of this, scientists and engineers are always striving to discover ways by which the quality as well as production of ferro silicon can be made better.

The way metals and alloys were being created, changed when ferro silicon came into the picture. It makes them more resilient to rust and heat resistant which are two important qualities for a lot of products. We can create at the output of this lines new things that simply were not possible to do in manufacturing and construction.

Xinda Industrial a professional ferro alloy ferro silicon industry, situated a key iron production zone, benefit from unique resource advantage. company covers an area of 30,000 square meters with a registered capital of 10 million RMB. Established over 25 years, company home four submerged arc furnaces as well as 4 refinery furnaces. We have more than 10 years of export experience have earned the trust of clients.

Xinda are company with more than 10 years export experience mature team provide professional serves customers. provide all ferro silicon industry of customized products, including the required, size, packing and more. We equipped with range modern production equipment and the security-secured logistics system that guarantees a quick and smooth delivery to location within the agreed upon time.

Xinda is manufacturer is primarily focused on the silicon series, like ferrosilicon, calcium silica ferro silicon magnesium, ferro chrome, high carbon silicone, silicon slag, etc. warehouse holds approximately five thousand tons. have long-term relationships numerous steel mills, distributors, both locally as well as internationally. global reach ferro silicon industry more 20 countries, including Europe, Japan South Korea India Russia.

Xinda certified by ISO9001, SGS other ferro silicon industry. have advanced and complete chemical inspection analysis equipment tested analytical methods that offer an independent guarantee the production top-quality products. Strict Inspection and control raw materials. Make prior to production, during production as well as final random inspection. We support third-party SGS, BV, AHK).