Ferro silicon magnesium when added to the steel during its production helps in enhancing the quality of steel. It is important because it extracts the harmful substances called impurities from the steel. Such impurities include sulfur and oxygen. When added to the steel, ferro silicon magnesium helps to eliminate these other impurities and duplicate a much more powerful in addition to durable finish for usage many functions.

Besides adding to the flowability, ferro silicon magnesium also prevents shrinkphenomina that occurs in the cast metal. Defect: When a mistake occurs (howsoever small), resulting in poor quality of the final usable product, it is considered as defect. We make things using casting, and strengthened them considerably with ferro silicon magnesium. This is the reason why ferro silicon magnesium plays a major role in casting process.

Ferro silicon magnesium alloys have a few very special qualities that make it great for lots of different potential work in industries. For instance, these alloys are renowned for their incredibly high strength. Iron and its mixed metals have a high tensile strength (ability to resist being pulled apart) – they are good for making things which need to go under stress, such as in machines or cars.

So, we are going to look for a better explanation of metal properties which leads us towards the actual answers- strength and ductility. Strength is the maximum pressure that a metal can withstand before it breaks. Whereas flexibility is the measure of how easily a metal can be bent, stretched or pressed without breaking. These two qualities are vital to ensure they operate well for specific applications across the industry.

Ferro silicon magnesium is used for strength as well flexibility of metals. When added to steel, it increases the strength of that material. This process eliminates any impurities which can adversely effect the strength of metal. This is risk-free for the steel as when it presses, this will certainly not match any type of openings onto it and also by cleaning up eh steel utilizing ferro silicon magnesium one can boost themean strength so that they could endure even more stress prior to wreckage.

As much as ferro silicon magnesium is great for the making of steel and other products, its effect on environment should not also be forgotten. The production of ferro silicon magnesium can lead to pollution and damage our planet. A lot of companies are aware and trying to work on solutions for cleaner production. They are concentrating on deploying pollution-resistant methods and minimizing absolute waste.

ConclusionImporting ferro silico manganesed from Indian producers can be considered a both positive and negative in the manufacturing point of view, for some manufacturer it also haspositive effects on elements. It does so, for instance, by enhancing the quality of steel and other metals to reduce waste. Stronger metals last for a longer time: this entails goods produced from them won't require to be replaced nearly as much. This would potentially reduce overall waste and help move away from linear (take, make, disposable) product life cycle to a circular economy.

Xinda has 10 years' experience in exporting provides professional services customers. provide all kinds of custom-made products meet specific requirements, like, size, packaging, more. are equipped with most comprehensive set of modern production equipment as well as the secure logistics system will ensure a smooth speedy delivery at final ferro silicon magnesium within the stipulated time.

Xinda is accredited through ISO9001, SGS other certification. have latest and most complete chemical inspection analysis equipment tested analytical methods that offer unambiguous guarantee for the production top-quality products. Strict incoming inspection control of raw materials. Make prior to production, during production, and final ferro silicon magnesium inspection. We support third-party SGS, BV, AHK).

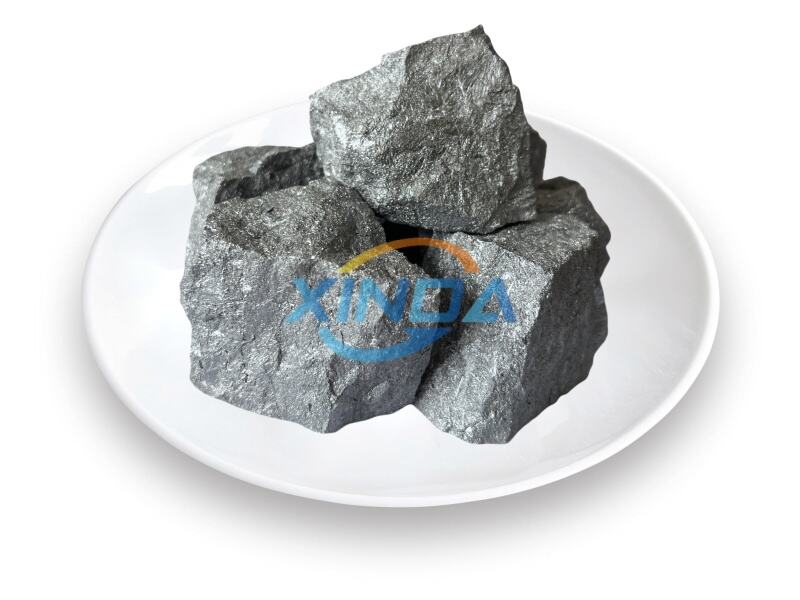

Xinda manufacturer concentrates on silicon series such as ferrosilicon. calcium silica and ferro silicon magnesium. chrome, high carbon silicon, silica slag, and so on. warehouse has around 5,000 tones. long-term relationships with various steel mills distributors both locally overseas. Covering more than 20 countries regions across the globe, which includes Europe, Japan, South Korea, India, and ferro silicon magnesium.

Xinda Industrial a professional ferro alloy manufacturer, situated in key iron ore ferro silicon magnesium zone, we benefit from unique resource advantage. Our facility covers space 30,000 sq meters with registered capital of 10 million RMB. Established for over 25 years, company home to four submerged arc furnaces four refinery furnaces. have over 10years export experience have earned the trust of its customers.