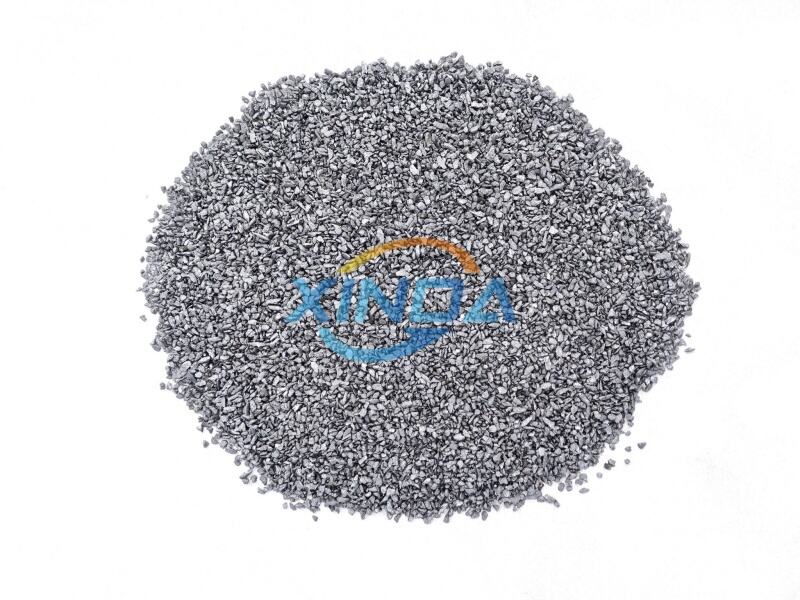

Fesi Ferrosilicon Fesi ferrosilicion There is a special metal that we use on daily basis; this particular metalis used for everything and you might not have realized how muchou need the material. Cast this unique mix from 2 different steels are iron and also silicon. When these metals are mix with each other we call it an alloy. Alloy: An alloy is a combination of different metals that are suitable for each other. Fesi Ferrosilicon is widely used in the production of steel, which can be found surrounding us every day as cars, buildings also household appliances. It is used in various forms of occupations and therein it has a variety of applications across sectors.

The mixture of the iron and silicon is called Fesi Ferrosilicon. This is one of the reasons why it remains a popular steelmaking process. Steel: A solid, powerful metal why which is perhaps used across a range of industries. It is famously used in the construction of houses, cars and even airplanes. Whenever steel is produced, hot molten iron contains added Fesi Ferrosilicon. This process helps iron stronger and better. Fesi Ferrosilicon enhances the strength of metals, which can be used for different uses and this makes it very important in various sectors.

When it comes to cast iron, the Fesi Ferrosilicon is very useful Cast iron is a dense and strong metal that has been used to make many things over the years, including pots and pans, pipes, parts for machines. Cast iron is manufactured by melting iron, and casting it into molds of requisite shape that involve addition of alternate compounds like Fesi Ferrosilicon. His addition enhances the quality of cast iron, making it more robust and durable. Especially in numerous industries, it allows for the construction of powerful machines and tools that can have a long service life even with repeated use.

One of the significant applications of Fesi Ferrosilicon is in producing electrical transformers. Electrical Transformers: These devices are responsible for changing one voltage of electricity into another. This process is crucial to producing and distributing energy for homes and industry. Adding Fesi Ferrosilicon to the transformers, aid them for more efficiently working; hence increase their reliability. This allows electrical transformers to last longer without the need of maintenance for a long time. This helps save time and money down the line.

Fesi Ferrosilicon is also widely used in the welding industry. Welding is the process of fusing to pieces of metal together using heat and pressure. Heating, however this in some cases can also weaken the metal; Fesi Ferrosilicon is added during welding so that it can remove even minute traces of oxygen from the metal. Oxygen has to be taken out because if left in, the metal can oxidize and lose strength. This leads to a robust and permanent connection which is vital for many industries ranging from construction, automotive manufacturing etc. One part where we need strong joints is just in regard to safety of structures and vehicles.

Finally but not least, Fesi Ferrosilicon also makes better aluminum products. Aluminum is a lightweight and high strength metal, so it has been widely applied in the aviation field, automotive industry etc. Adding Fesi Ferrosilicon strengthens aluminum products, making them more resilient. This is significant as it enables the development of more durable and lighter products applicable in various sectors.

Xinda is manufacturer is primarily focused on the silicon series, like ferrosilicon, calcium silica ferro silicon magnesium, ferro chrome, high carbon silicone, silicon slag, etc. warehouse holds approximately five thousand tons. have long-term relationships numerous steel mills, distributors, both locally as well as internationally. global reach fesi ferrosilicon more 20 countries, including Europe, Japan South Korea India Russia.

Xinda over 10 years expertise in exporting offer expert services to customers. offer a wide range customized products including special requirements sizes, packaging, etc. modern production equipment, along with safe fesi ferrosilicon system assures efficient and prompt delivery to final destination.

Xinda accredited through ISO9001, SGS other certification. have advanced and complete chemical inspection analysis equipment standard analysis fesi ferrosilicon that provide an independent guaranteed production top-quality product. Strict in-coming inspection monitoring of raw materials. Make the pre-production, production, and final random inspection. We accept third-party SGS, BV, AHK).

Xinda Industrial a professional ferro alloy manufacturer, situated in a key iron ore production zone, we benefit from unique resource advantage. company covers space of 30,000 sq meters with registered capital of 10 million RMB. Established for over 25 years, company has 4 submerged arc furnaces and four refineries fesi ferrosilicon. have over 10years export experience, we have won the trust of clients.