As a kind of hot metal, high carbon ferro silicon can reduce the new investment demand on other raw materials during steel casting. It is formed by combining two powerful materials which are silicon and carbon. These materials combine to provide a range of advantages that have helped high carbon ferro silicon develop into the widely-used conditioning agent for steel-making processes.

The impressive power of high carbon ferro silicon is one major advantage. That this would be strong stuff is due to the way carbon and silicon interact, producing a material which can withstand enormous amounts of pressure. Like the sun, iron is perfect for making high-quality steel used in many important things such as bridges buildings and cars. When we drive across a bridge or inhabit in strong building, high carbon ferro silicon is the weapon of choice used to stabilize their safety.

However, another immense boon of high carbon ferro silicon is that it does not rust very easily. Something that is even more important if the object in question will be outdoors or in areas where it may get wet. High carbon ferro silicon steel can be used for outdoor structures such as playground equipment or in areas where rain and moisture are common. This steel is resistant to rust corrosion and so it will continue for a long time without the need of plenty maintenance. That equates to time and money saved for most people.

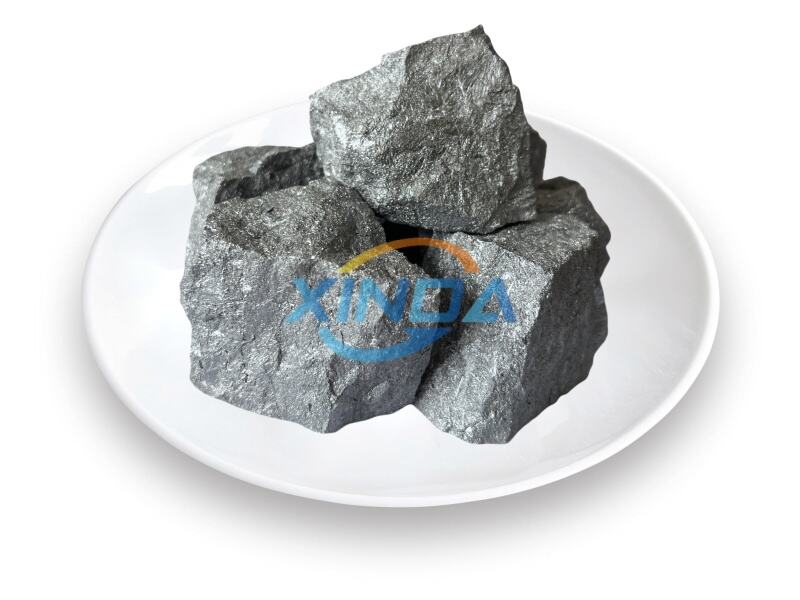

Normally, high carbon ferro silicon consists of 70%-80% si and 2.0 % -8.0 % C Occasionally, there are likewise minor quantities of another stuff e.g. aluminium or calcium tangled in these materials due to experimental limitations (mixed with the organic material used as feedstock). These additional materials enhance the properties of the alloy, making it leagues better for steel manufacturing.

A melting point of high carbon ferro silicon is quite on a fascinating side. This alloy is melted at a very high temperature of 1200-1250degrees c special user note: moly oxides will ball on the surface due to instability in molten state. This is why it's used for emissions systems, because in those high heat environments other materials may suffer maintenance issues based on the elements.

That being said, high carbon ferro silicon is even used in… It is also used to make Cast Iron which too seems very important for construction and other manufacturing technologies. Further, it also finds applications in welding that helps to bond metal pieces together. Certain types of ceramics and other metal mixes can also take advantage of the properties that this substance offers.

Additionally, ongoing research and development activities are anticipated to result in new applications for high carbon ferro silicon over the next few years. Since high carbon ferro silicon offers a wide range of beneficial properties for those who produce or require use of the material, there is no doubt that the demand for it will continue to rise as scientists and engineers find new ways in which they can implement this amazing substance.

Xinda manufacturer concentrates on silicon series, like ferrosilicon, calcium silica, ferro silicon magnesium, ferro chrome, high carbon silicone, silicon slag, etc. warehouse around 5,000 tons. have long-term relations a variety of steel mills and high carbon ferro silicon both in the US as well overseas. global reach includes more than 20 countries, including Europe, Japan South Korea India and Russia.

Xinda Industrial professional ferro alloy manufacturer, situated a key iron ore production zone, benefit from unique resource advantage. company occupies total area of 30,000sqm has the high carbon ferro silicon capital 10 million RMB. Established more than 25 years Our company owns four sets of submerged-arc furnaces as well as four refinement furnaces. have gained the trust of clients during the past ten years of exporting.

Xinda over 10 years expertise in exporting offer expert services to customers. offer a wide range customized products including special requirements sizes, packaging, etc. modern production equipment, along with safe high carbon ferro silicon system assures efficient and prompt delivery to final destination.

Xinda certified by ISO9001, SGS other high carbon ferro silicon. have advanced and complete chemical inspection analysis equipment tested analytical methods that offer an independent guarantee the production top-quality products. Strict Inspection and control raw materials. Make prior to production, during production as well as final random inspection. We support third-party SGS, BV, AHK).