Wheels are pretty old as far as inventions go, but cutting tools have improved quite a bit since then. However, nowadays we use cutting tools in many jobs where elements of the society that lived along with David did not have such a wide range on offer. Did you also know that creating and using these tools can be quite damaging to our planet? Enter Green Carbide(JNIEnv: GCJB) So, here we will learn what is Green Carbide and how it works through its importance towards the future of cutting tools.

Green Carbide offers a truly novel product — sustainable for the environment and economy at the same time. Carbide is also used as a material with high-hardness and toughness, which means it has the ability to cut through many types of materials. Making regular carbide is a dirty process that uses lots of energy and produces nasty gases that harm out planet.

Frequently Asked Questions Q: How is Green Carbide any different from regular carbide? Its creation is good for the environment, since it uses clean energy and safe materials. This makes it an excellent replacement for the traditional carbide. What is even more awesome, Green Carbide can do the same job at home and save business money. This breakthrough empowers the manufacture of quality cutting tools, without harming our world.

Not all cutting tools are the same, and now more companies care about their impact on the planet. That is why Green Carbide machinable material becomes the best choice for future cutting tools since it helps to lower environment load. There is a greater awareness growing in the industry that companies need to be conscious and reduce their carbon footprints, making Green Carbide ideal for many such organisations.

First of all, climate change is a serious issue that impacts everyone — even those in the cutting tool industry. Normal production of carbide heater produces a lot of harmful gases which causes global warming and it warms our planet. Green Carbide enables to solve this! Being manufactured with clean energy and safe materials means it does not have the same caustic effects on our environment.

Given the myriad benefits, it is not surprising that more companies are eager to employ Green Carbide. A lot of businesses are now doing the switch and reporting that they loved saving dollars while still showing off their love for mother nature. The applyer of the Green Carbide learn that it might save them some money and do good things for their planet while also (and especially) using higher qualitycitation needed.

Basically, Green Carbide are revolutionizing the cutting industry and it is impressive how far things have come in terms of cutting tools. Green Carbide is ideal for a company looking to reduce its environmental commitment as well and perform excellently. Businesses can get involved in saving the world — without compromising on quality or productivity.

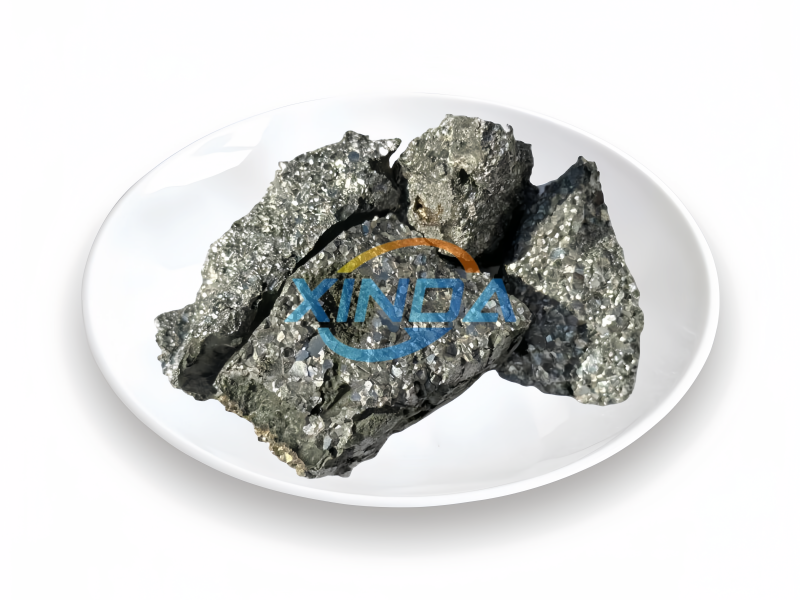

Xinda over 10 years' experience in exporting provides professional services customers. green carbide all kinds of custom products which include special needs such as size, packaging and so on. equipped with most comprehensive set modern production equipment and secured logistic system which assures a speedy and efficient delivery to desired destination within specified time.

Xinda certified by ISO9001, SGS other green carbide. have advanced and complete chemical inspection analysis equipment tested analytical methods that offer an independent guarantee the production top-quality products. Strict Inspection and control raw materials. Make prior to production, during production as well as final random inspection. We support third-party SGS, BV, AHK).

Xinda a manufacturer that primarily focused the silicon series like ferrosilicon, calcium silica, ferro silicon magnesium, ferro chrome, high carbon silicon, silica slag, and so on. green carbide stocked approximately five thousand tons. have long-term relationships with many steel mills, distributors in the US internationally. global reach includes more 20 countries including Europe, Japan South Korea India Russia.

Xinda Industrial a professional ferro alloy manufacturer, situated a key iron ore production green carbide, benefit from unique resource advantage. Our company occupies total surface 30,000 square meters with registered capital 10 million RMB. Established more than 25 years and has four submerged-arc furnaces and four sets refinement furnaces. We have gained the trust our clients during past ten years of exporting.