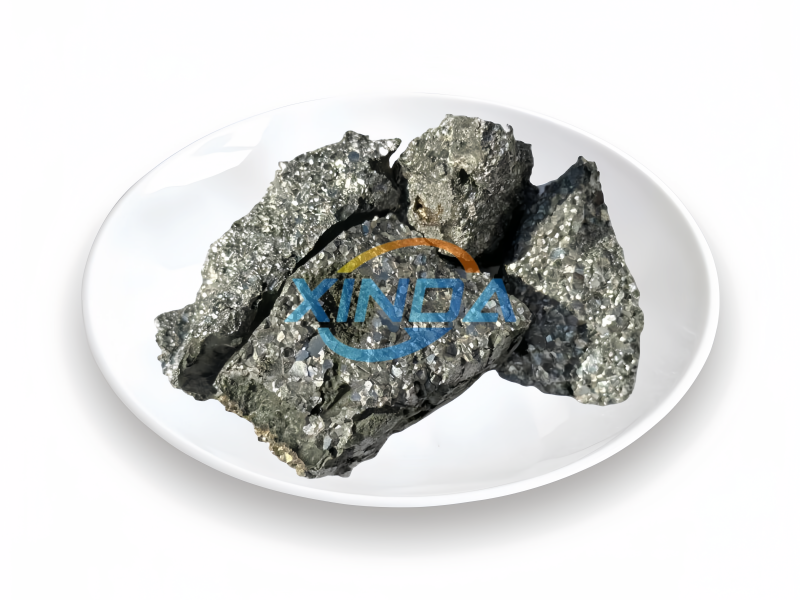

Did you ever wonder what makes steel so reliable and efficient? One key ingredient for making steel strong is LC Ferro Chrome. LC Ferro Chrome: LC Ferro Chrome is the blend of iron, chrome and carbon. This blend is actually important given that it utilized to help make stainlesssteel, a form of steel that performs certainly not rust. Stainless steel is all around us, from buildings and cars to kitchen appliances and even medical equipment.

Smelting the Ingredients: Smelting is accomplished when all of these elements ( iron, chrome and carbon ) are mixed together in a container called a crucible. Crucible: A strong container that melts feet because it can hold very hot materials. As it tolerates very high temperatures, which is necessary for the process.

Step 6: Melting mixture and pouring to molds When the metal is properly melted, we then have a liquid state in which can be poured carefully into the mold. A mold is a form into which liquid metal will solidify. A mold is particularly essential because the molding provides a shape to LC Ferro Chrome that remains later used as such.

Stainless Steel produced with LC Ferro Chrome is also more durable, in terms of clear Durability. This resulted in it being more permanent and sturdy than regular steel. Thanks to this strength, stainless steel is commonly used in products that must last a long time -such as kitchen appliances and tools.

Appearance: Another advantage of LC Ferro Chrome is it gives a polished look to the stainless steel. This polished appearance is quite attractive; hence it makes for shop displays, and home or building fixtures. Stainless steel is a popular choice for the simple fact that it looks good and is easy to clean.

LC Ferro Chrome is highly effective to produce stainless steel and this can be considered as the best, but it not only works well for these procedures than other types of ferro alloys. The most common alternative is associated with the presence of carbon in a higher percentage which have known as HC Ferro Chrome.

There are specific benefits as well as disadvantages attributed to both LC Ferro Chrome and HC Ferro Chrome. Many times this comes down to the individual requirements of an application. Ie, LC Ferro Chrome is employed when we predict for stronger and extremely robust material. If a contrasting quality of property such as exact Carbon level is needed, then the HC Ferro Chrome can be chosen.

Xinda has been accredited by ISO9001, SGS other lc ferro chrome. have modern fully equipped inspection analysis equipment, standard methods for in-coming inspection raw materials. Perform random inspections during production, during process then the final inspection.

Xinda Industrial a professional ferro alloy manufacturer, situated a key iron ore production zone, benefit from unique resource advantage. company covers an area of 30,000 square meters with a registered lc ferro chrome of 10 million RMB. Established since 1995, company four submerged arc furnaces, as well as four refinery furnaces. have more than 10 years export experience, have won trust of customers.

Xinda over 10 years' experience in exporting provides professional services customers. lc ferro chrome all kinds of custom products which include special needs such as size, packaging and so on. equipped with most comprehensive set modern production equipment and secured logistic system which assures a speedy and efficient delivery to desired destination within specified time.

Xinda manufacturer focuses mainly silicon series, such as ferrosilicon calcium silica, ferro silicon magnesium, ferro chrome, high carbon silica, silicon slag. warehouse holds approximately 5,000 tons. have long-term lc ferro chrome several steel mills, distributors, both locally as well as overseas. global reach extends to more than 20 countries, which includes Europe, Japan South Korea India Russia.