A very strong and useful material for a variety of other industries, off-grade silicon. But what does it mean to be off-grade, actually? When you are told that silicon is off-grade, it implies the same thing. It happens when there are too many impurities mixed in with the silicon, which can impact it from working.

In the production of all clean silicon, secondary grade is produced. Producing pure silicon is by no means a straightforward process. Magione differs in that it takes several, very long steps to purify the silicon and get rid of any impurities or elements unwanted in the final materials. Ahhh, the production… simple on paper but a world of trouble sometimes(phase). Mistakes can arise or errors invariably occur and this can lead to silicon being categorised as off-grade. So rather than being a high-end material, it might also not meet the strict demands necessary for certain applications.

There are up sides and down sides of using off-grade silicon that people need to take into account. Some companies tend to use off-grade silicon since it is cheaper. This is something that can be appealing for manufacturers who want to reduce costs. Moreover, off-grade silicon can also be used in some manufacturing processes where highest grade is suboptimal. Still, using off-grade silicon has its shortcomings. Which in turn means a lowerening product quality. Manufacturing issues: The inclusion of off-grade silicon into the manufacturing process has a potential to create difficulties in producing these materials, which may ultimately affect your end product. Certain objects, if produced with off-grade silicon may neither meet strength standards (that e.g. in case of glazing might break), or functional requirements — an issue both for producers and consumers.

Production and application of off-grade silicon are potentially disruptive to the environment, The production of off grade silicon frequently creates excesses in the form of waste — and air pollution, worse than the creation process for pure silicon. More waste will definitely lead to more pollution in the air and because of that we may end up adding into something horrible for our planet. Secondly, use of this off-grade silicon in many products ends up contaminating and causing other types of damage to the natural environment which are important downstream impacts.

But, there are sustainable answers which in turn would help us get rid of the problem of off-grade silicon. This includes recycling, one of the solutions. Recycling off-grade silicon can help reduce waste and pollution created in the production process. It saves precious resources and mitigate the adverse environmental impact of manufacturing. We can recycle in order to feel new things that maybe wouldn't have the chance otra life, and this would change way our planet thinks.

The improvements to address off-grade silicon challenge in innovations by innovators One intriguing notion is to develop more efficient cleansing strategies that could lead on how you can synthesize purer kinds of silicon. That wo There wouldn be less need of off-grade silicon in first pace. However, challenges remain for the development of these new techniques. Understanding how to make these processes work well, efficiently and cost effectively is key to getting more widespread adoption of in industry.

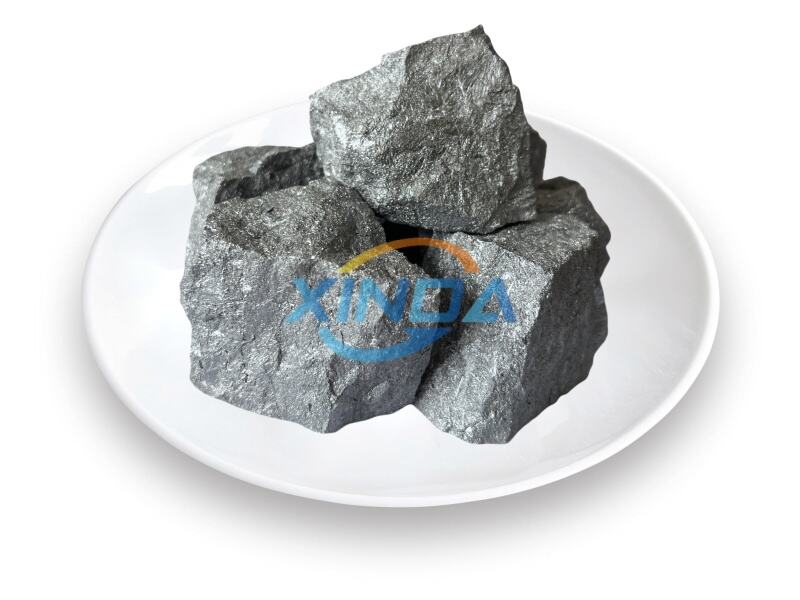

Xinda has more than ten years' experience exporting. team experts who can provide professional services customers. We offer every kind custom-made, such special requirements, sizes, packing and so on. are equipped with a range modern production equipment, well as the security-secured logistics system that assures a speedy efficient off grade silicon to the destination within the stipulated time.

Xinda manufacturer focuses mainly silicon series, such as ferrosilicon calcium silica, ferro silicon magnesium, ferro chrome, high carbon silica, silicon slag. warehouse holds approximately 5,000 tons. have long-term off grade silicon several steel mills, distributors, both locally as well as overseas. global reach extends to more than 20 countries, which includes Europe, Japan South Korea India Russia.

Xinda Industrial a professional ferro alloy manufacturer, situated in key iron ore off grade silicon zone, we benefit from unique resource advantage. Our facility covers space 30,000 sq meters with registered capital of 10 million RMB. Established for over 25 years, company home to four submerged arc furnaces four refinery furnaces. have over 10years export experience have earned the trust of its customers.

Xinda is accredited through ISO9001, SGS other certification. have latest and most complete chemical inspection analysis equipment tested analytical methods that offer unambiguous guarantee for the production top-quality products. Strict incoming inspection control of raw materials. Make prior to production, during production, and final off grade silicon inspection. We support third-party SGS, BV, AHK).