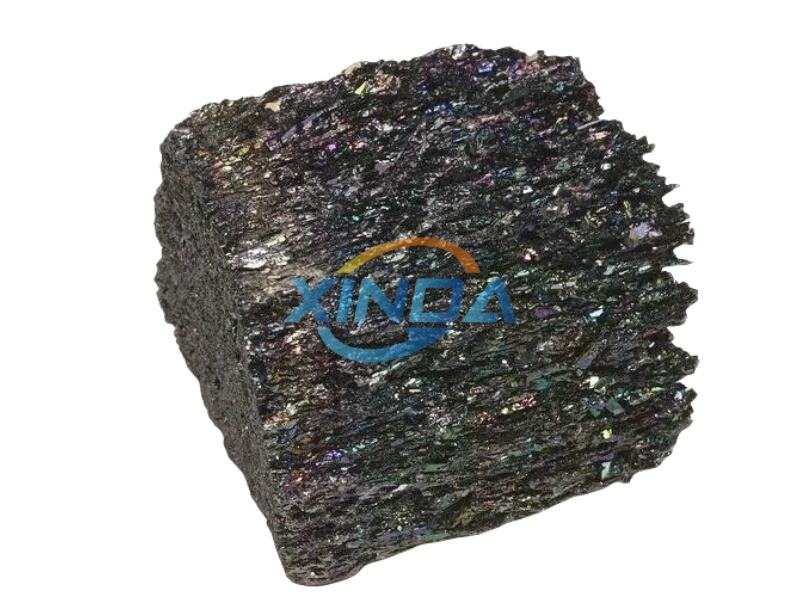

SiC 70 is a Here describes, How to Make From Altharwa Materials from Si Element and C element. The material is very durable and can withstand far higher temperatures without liquefying. SiC 70 is used by a variety of businesses and industries as it has many great benefits that they can take advantage of.

One of the main reasons to consider SiC 70 is due to its ability to withstand higher voltages than other materials. This makes it ideal for electronics and power hungry devices. SiC 70 even more effective — that is, as it helps to save energy. This energy savings results in lower costs, a significant advantage to the business looking for ways to run more affordably.

The SiC 70 variety is very powerful and heat resistant, which still represents many factories. Given its ability to withstand high temps, it is often well suited for use in heat systems & industrial furnaces. It can handle a large amount of High Voltage and Current as well; this makes it suitable for high power electrical circuits. Using SiC 70 in machines and equipment means that they run better, longer which is crucial when it comes to the manufacturing environment.

The SiC 70 is also an important one for the automotive area. This is used to enhance the performance of electronic components in vehicles. With SiC 70 technology, car manufacturers would be able to reduce the size and weight of electrical components while improving their overall strength and performance. Which is significant because it means cars consume less fuel and also emit fewer harmful substances. With its objectives of reducing fuel consumption and CO2 emissions, SiC 70 makes a significant contribution to the environment by keeping cars in top condition for longer.

Alternative formulations of SiC 70 are advanced materials that offer the ability to re-imagine what is possible in power electronics. It is unique in the way that, it can be employed mains electrical circuits due to its high power and many other significant uses. With wider application of SiC 70 technology in various industries, we should be looking forward for even more interesting and innovative advancements made using the field power electronics. New products and technologies which we can't even dream up.

Xinda is accredited by ISO9001, SGS and other certification. are equipped with most advanced comprehensive equipment for chemical inspection analysis standardized analysis methods provide unambiguous SiC 70 for production of top-quality products. Strict inspection and control of the incoming flow of raw materials. Make the pre-production, production and final random inspection. We support third-party SGS, BV, AHK).

Xinda Industrial a professional ferro alloy manufacturer, situated in a key iron ore production zone, we benefit from unique resource advantage. Our company SiC 70 area of 30,000 square meters with registered capital of 10 million RMB. Established for over 25 years, company has 4 submerged arc furnaces and four refinery furnaces. have over 10years export experience, have won the trust customers.

Xinda over 10 years of experience SiC 70 experienced team that can offer professional products for customers. offer every kind customized, like special requirements, sizes, packing etc. state-of-the-art production equipment together with our secure logistic system, ensures a smooth timely delivery final destination.

Xinda is an established manufacturer. concentrate silicon series items, including ferrosilicon. Calcium silicon, ferro silicon magnesium, high carbon silicon, silicon slagged. warehouse typically stocks around five SiC 70 tons stock. have long-term agreements numerous steel mills and distributors both locally as well as overseas. Covering more 20 countries regions across the globe which includes Europe, Japan, South Korea, India, Russia.