2006 Metallurgical silicon is a significant product for various industries such as metal fabrication, construction, and others. Understanding why its price changes can help companies take better action. Trends, Causes and Thoughts on the Price of Metallurgical Silicon Author:Michelle Date:2020-08-14 Metallurgical silicon price fluctuations, as well as companies how to deal with price fluctuations will let us to see today.Garberji once said,Often can't get it, can't control it;Only those who have it can control it.

The price of metallurgical silicon can rise and fall for many reasons, such as how much, and how little, is desired. Tracking these trends can help businesses anticipate price shifts and make wise decisions. For instance, if more people demand metallurgical silicon, the price could go up. If there is an oversupply in the market, the price could decrease. Tracking these trends helps companies stay prepared and adjust their plans if necessary.

The price of metallurgical grade silicon can be impacted by a number of things. One of those things is the cost of producing it — things like the energy, workers and materials. There are ways companies can massage these costs by increasing production, applying new technology and seeking out different suppliers. Oh and regulatory; that also has a price, governments have rules and laws. Knowing in advance about changes in these rules, companies can adjust the way they do business and the prices they charge to avoid issues.

There are many industries that demand the global desire for metallurgical silicon, such as cars, electronics, solar energy, etc. Companies that understand how demand and supply operate can guess what the market may do, and rearrange production accordingly.” “If there is a big demand for metallurgical silicon in solar energy, companies can expand capacity,” he explains. If one industry is struggling, businesses can seek new customers, which can mitigate the impact on their bottom lines.

Geopolitical stuff (trade issues/tariffs) can move Metallurgical silicon prices quite a bit. For example, political events could disrupt the supply chain globally if one of the key producers of metallurgical silicon, for instance, suffers political challenges or something else that leads to price changes. Companies can manage these risks by diversifying their supply base, considering entering new markets and keeping abreast of global news. Monitoring these developments will also enable companies to readjust their planning and to keep their business safe from likely disturbances.

In the face of fluctuating prices for metallurgical silicon, companies may want to find different ways to reduce their exposure to price risk. One is to enter into long-term commitments with reliable suppliers to stabilize prices and access steady sources. Firms may also hedge against price fluctuations by engaging in the futures market. Then, by devoting resources to research and new technology, companies can figure out how to produce at lower costs, and how to work more effectively.

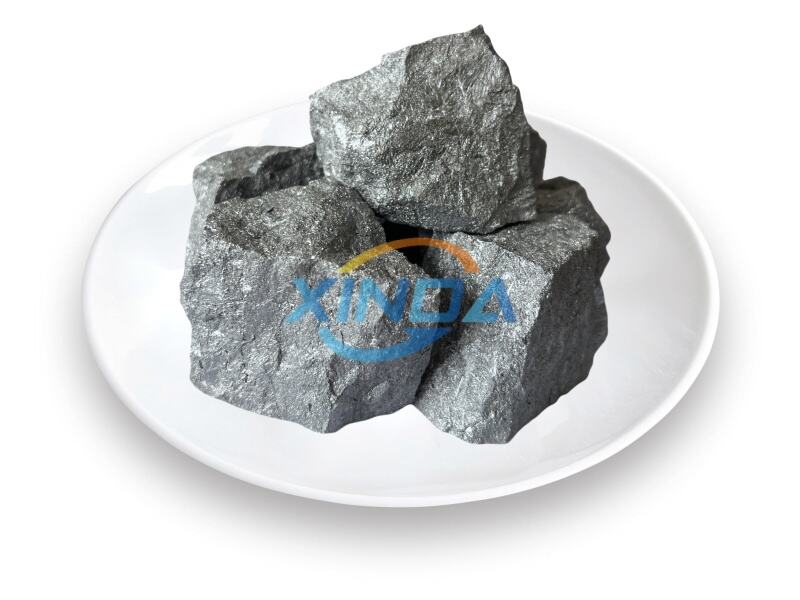

Xinda over 10 years expertise in exporting offer expert services to customers. offer a wide range customized products including special requirements sizes, packaging, etc. modern production equipment, along with safe metallurgical silicon price system assures efficient and prompt delivery to final destination.

Xinda is manufacturer is primarily focused on the silicon series, like ferrosilicon, calcium silica ferro silicon magnesium, ferro chrome, high carbon silicone, silicon slag, etc. warehouse holds approximately five thousand tons. have long-term relationships numerous steel mills, distributors, both locally as well as internationally. global reach metallurgical silicon price more 20 countries, including Europe, Japan South Korea India Russia.

Xinda Industrial professional ferro alloy manufacturer, situated a key iron ore production zone, benefit from unique resource advantage. company occupies total area of 30,000sqm has the metallurgical silicon price capital 10 million RMB. Established more than 25 years Our company owns four sets of submerged-arc furnaces as well as four refinement furnaces. have gained the trust of clients during the past ten years of exporting.

Xinda certified by ISO9001, SGS and other certification. have latest most complete equipment chemical analysis and inspection and standardized analysis methods provided an metallurgical silicon price guaranteed production top-quality product. Strict Inspection and control of raw materials. Make an inspection prior to production, during manufacturing as well final random inspection. We support third-party SGS, BV, AHK).