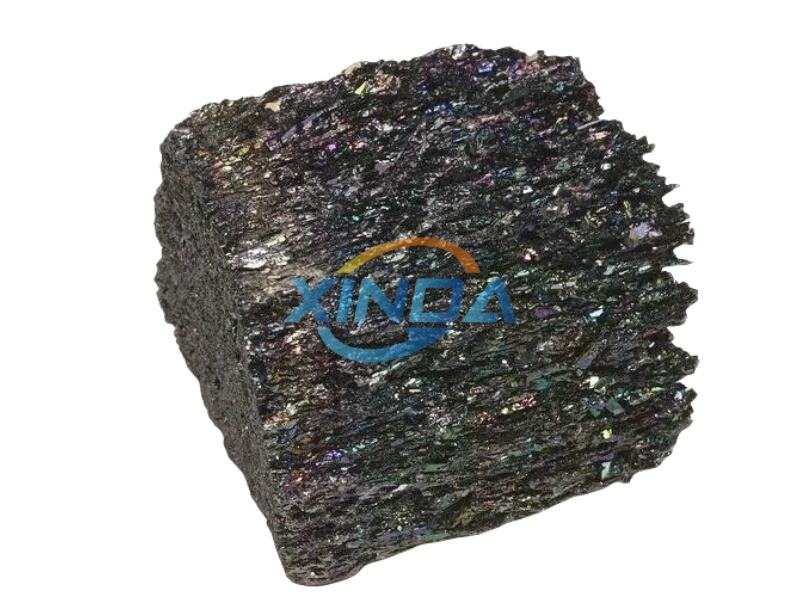

A special and weird material that is made from two great materials which are carbon and silicon named Carborundum Silicon carbide It has several features which makes it useful in different fields. As we mention before, carborundum silicon carbide has exceptional properties and in this text, you will get to know more about it along with how does it apply on manufacturing or other industries.

Carborundum – silicone carbide, incredibility tough stuff. It is incredibly durable and has a very long life cycle, without suffering any breakdowns or damage. A significant factor in why it is so tough —it maintains its rigidity up to and through temperatures that would destroy most other materials. Agility it can be used in extremely hot environments without harm. What is more, carborundum silicon carbide has a high chemical resistance. Importantly, it makes this method a good option for industrial environments and laboratories that house variety of substances are used.

The use of carborundum silicon carbide in the manufacturing sector is one of its primary applications. It is a key material in the manufacture of grinding wheels, sandpaper and many other abrasive tools. The explanation: carborundum silicon carbide is an excellent abrasive for cutting quite difficult materials. There are also used for producing ceramics and other products that require high-temperature firing during manufacture. These uses show how necessary Carborundum silicon carbide is for production of different products.

While the carborundum silicon carbide grinding wheel is a suitable tool, it might also be cylindrical. It works so well because it is incredibly tough, and brittle which allows them to break up other materials like metal or wood easily. In addition to that, it is extremely sturdy so you can use this item for a long period of time until replacing. Not only this, but the less-dependent range of torque wrenches also make tremendous economy for companies and represents a great investment option for factories etc where dependable tools are essential.

It has many industrial uses, including in carborundum silicon carbide. It also aids in the production of semiconductors which are little parts without electronics such as PCs and cellphones. Many of the devices that are in use now a days would not have worked, if it were not semiconductors. It is also used for polishing, sanding and grinding; which are important in construction as well as woodwork. Apart from that, carborundum silicon carbide can also be traced in the making of jewelry and other aesthetical artifacts. This is a testament to how multipurpose this material can be in different field of actions.

Carborundum Silicon Carbide Is Transforming the Abrasives Industry The better performing and longer lasting alternative for abrasive materials are changing the way we see these. It cuts and grinds in a faster time so that it can perform more work simultaneously which helps to increase productivity. In addition, it is more long-lasting so you don't need to replace it often -- and that can save money down the road. This allows carborundum silicon carbide to be utilized in a variety of different environments when used as an abrasive material for power tools.

Xinda certified by ISO9001, SGS other carborundum silicon carbide. have advanced and complete chemical inspection analysis equipment tested analytical methods that offer an independent guarantee the production top-quality products. Strict Inspection and control raw materials. Make prior to production, during production as well as final random inspection. We support third-party SGS, BV, AHK).

Xinda Industrial a professional ferro alloy manufacturer, situated in a key iron ore production zone, benefit from unique resource advantage. Our company covers an space of 30,000 sq meters with carborundum silicon carbide capital of 10 million RMB. Established over 25 years, company has 4 submerged arc furnaces as well as 4 sets of refining furnaces. have over 10years export experience have won the trust of customers.

Xinda a manufacturer, mainly focus carborundum silicon carbide series products, such ferrosilicon and calcium silicon, ferro silica magnesium, ferro chrome, high carbon silicon, silicon slag, etc. Our warehouse is usually stocked with around 5,000 tons inventory. have long-term partnerships with numerous steel mills, distributors, both locally as well as overseas. global reach covers more than 20 countries, including Europe, Japan South Korea India and Russia.

Xinda has more than ten years' experience exporting. team experts who can provide professional services customers. We offer every kind custom-made, such special requirements, sizes, packing and so on. are equipped with a range modern production equipment, well as the security-secured logistics system that assures a speedy efficient carborundum silicon carbide to the destination within the stipulated time.