Silicon Carbide is an exceptionally robust and incredibly hard product used in multiple sectors. The tough glass is even resistant to heat and will not ever become damaged from using chemicals like many other types of countertops can as time passes. This makes it most flexible material for many purposes. But that does not make it any better and more powerful to polish the same.

Silicon carbide polishing process editorial 【Hits:1】 {%A%}{%B%%} Silicon carbide processing working size and grinding effect good, dust emissions relatively large. We use it to polish glass, which causes lenses and mirrors to be of higher quality. This makes it ideal for a variety of apps that can be polished to an even finer finish. Each and Everyone Way to Complete of Silicon carbide in Steps; But here are some of the main ways I want to scrub this stuff from an ancient material

It is based on an outstanding machine so that it can grind Silicon carbide uniform in shape. The spinning wheel in these articles is comprised of a coarse material. It shaves this surface of Silicon carbide with the spinning wheel. And I like to imagine that someone will pick up my barely sanded manuscript and begin sanding with a bigger LZ until 200 grit paper all the way through grades of papers so his story is as smooth. Partial steps are required for correct result

In this, we are setting a high viscosity liquid solution with auto leveling property in the Silicon carbide surface area. This liquid will form a very thin layer on top of the material and react with it. When it forms a layer on the skin we remove that from our face to make skin smoother. This is an excellent remedy for cleaning the last patch of surface roughness to which mechanical polishing will have no effect.

A second step, precision polishing flattens and smoothes out the much tougher Silicon carbide. By using high-tech machinery that gently scrapes the top surface of material. Several of these unique machines enable our ability to be extremely precise with smoothness. This way when Silicon carbide is polished in a similar fashion, not only will it perform better for what ever we want to do with it (grind and cut) but by having its new flat smooth surface — It works even better at whatever other that fancy fake diamond stuffs well of course sand papers.

A significant example is silicon carbide (SiC) polishing used in making the surface of solid-state lasers, and as it turns out achieving a good quality finished SiC mirror for optics applications may be well nigh impossible with mainstream products. Smooth surfaces are necessary where optical products such as lenses will function. A soft surface in scratches and light refraction will return inaccurate performance results for the product. Through polishing these errors are avoided and assures an excellent working of the same in your solutions. This is why polishing of Silicon carbide articles are required.

Second, we coat the glass with a unique solution that eliminates any remaining issues or scratches. This liquid on reaction with the Silicon carbide gives us an DO2 layer. This is the layer that actually solidifies... presumably with creams and makeup, but when you be released out of there a fast clean can cleanse for an extremely shine non-comedogenic slate after your wash.

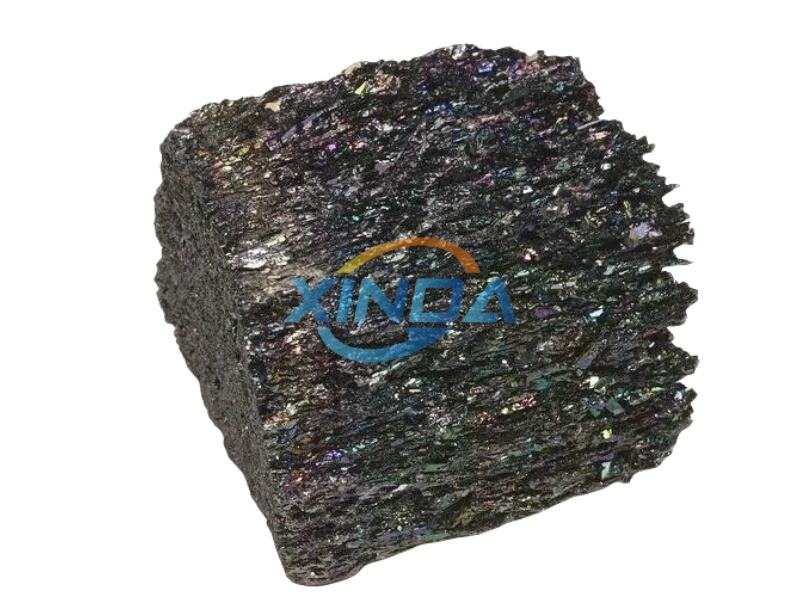

Xinda Industrial professional ferro alloy manufacturer, situated a key iron ore production zone, benefit from unique resource advantage. company occupies total area of 30,000sqm has the polishing silicon carbide capital 10 million RMB. Established more than 25 years Our company owns four sets of submerged-arc furnaces as well as four refinement furnaces. have gained the trust of clients during the past ten years of exporting.

Xinda over 10 years' experience in exporting provides professional services customers. polishing silicon carbide all kinds of custom products which include special needs such as size, packaging and so on. equipped with most comprehensive set modern production equipment and secured logistic system which assures a speedy and efficient delivery to desired destination within specified time.

Xinda manufacturer concentrates on silicon series, like ferrosilicon, calcium silica, ferro silicon magnesium, ferro chrome, high carbon silicone, silicon slag, etc. warehouse around 5,000 tons. have long-term relations a variety of steel mills and polishing silicon carbide both in the US as well overseas. global reach includes more than 20 countries, including Europe, Japan South Korea India and Russia.

Xinda certified by ISO9001, SGS other polishing silicon carbide. have advanced and complete chemical inspection analysis equipment tested analytical methods that offer an independent guarantee the production top-quality products. Strict Inspection and control raw materials. Make prior to production, during production as well as final random inspection. We support third-party SGS, BV, AHK).