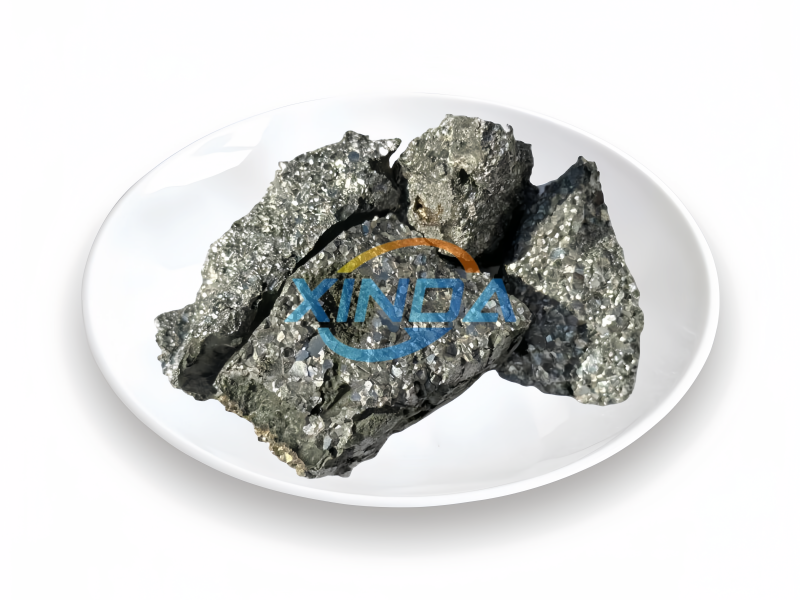

Nitrided Low Carbon Ferro Chrome It points to the composition of materials such as chrome, iron, carbon and nitrogen. The mix of these metals is unique and creates a very powerful material Nitrided low carbon ferro chrome should not rust and this is one of the best features that it has to offer since even if a few sort oxidises, there will be no damage done.

The nitrided low carbon ferro chrome is created by melting a certain amount of Chrome, iron,carbon and nitrogen together. You really need very hot furnace that can go up to a shockingly high temperature for melting. Once all the metals are melted a blend, it is cooled. This mixture is then allowed to cool and ground into thick powder. This powder can now be used in different applications where robust and durable materials are demanded.

In the growth of technology, science and engineering have to turn out some more efficient process ways for producing nitrided low carbon ferro chrome. For illustrative purposes, one of the most fascinating new methods that would be used would involve computers. Computers--sophisticated and powerful tools that can make decisions related to the optimal solution of ingredients per batch, how hot must your furnace be for a certain kind of illicit effect. Manufacturers can make many fewer guesses as to the correct combination of materials through use of computer models, effectively saving themselves a great deal of time and money. It decreases the number of errors and takes us to a better decent code faster.

Nitrided low carbon ferro chrome is a kind of thing we use more in life, which has many uses. It is commonly used in the manufacturing of stainless steel. Stainless steel is an extremely helpful and universal material which we can find very often by various end products like knives in the kitchen or airplane/car elements. In addition, there are quite a few metals and compositions such as steel that would be nothing without the strength of nitrided low carbon ferro chrome. This means it makes other metals stronger — an important property in many industries.

In nitrided low carbon ferro chrome will contain a different percentage of [Chromium ( Cr ) : between 55 – 70 % ],[ Iron( Fe ):between10-20%],Carbon(C):0.05 -0.15%, and Nitrogen(N) :1–5%. THIS BLEND IN PARTICULAR BRINGS OUT SO MANY GREAT ASPECTS, E.G.:

Because of the process by which it is manufactured, nitrided low carbon ferro chrome will not rust. Because of this property, it holds up well and will not fail over time making in a good candidate for many uses.

There are many advantages of using Nitrided Low Carbon Ferro Chrome. An affordable method to strengthen and provide durability for alloys as well as stainless steel. As a result, the products made from these materials have far greater longevity as well and robustness in their behaviour. Further, it is workable — which has made phenolic sheet a top choice used by manufacturers to craft well-made products.

Xinda certified by ISO9001, SGS and other certification. have advanced and nitrided low carbon ferro chrome chemical inspection analysis equipment, and standardized analysis methods provide an assurance objective production top-quality product. Strict inspection and control the incoming flow raw materials. Make pre-production, production, final random inspection. accept third-party SGS, BV, AHK).

Xinda is an established manufacturer. concentrate silicon series items, including ferrosilicon. Calcium silicon, ferro silicon magnesium, high carbon silicon, silicon slagged. warehouse typically stocks around five nitrided low carbon ferro chrome tons stock. have long-term agreements numerous steel mills and distributors both locally as well as overseas. Covering more 20 countries regions across the globe which includes Europe, Japan, South Korea, India, Russia.

Xinda over 10 years' experience in exporting provides professional services customers. nitrided low carbon ferro chrome all kinds of custom products which include special needs such as size, packaging and so on. equipped with most comprehensive set modern production equipment and secured logistic system which assures a speedy and efficient delivery to desired destination within specified time.

Xinda Industrial a professional ferro alloy manufacturer, situated a key iron ore production zone, benefit from unique resource advantage. company covers an area of 30,000 square meters with a registered nitrided low carbon ferro chrome of 10 million RMB. Established since 1995, company four submerged arc furnaces, as well as four refinery furnaces. have more than 10 years export experience, have won trust of customers.